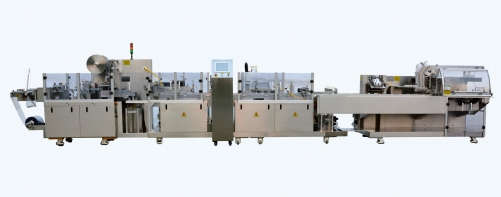

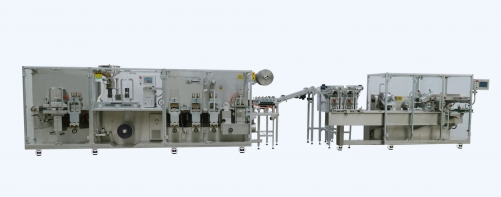

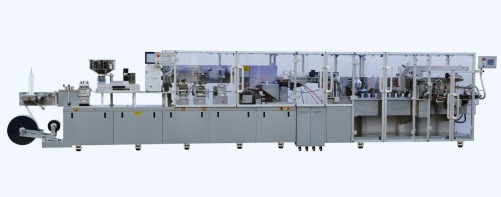

Blister And Cartoning Line

This Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for medium batch production.

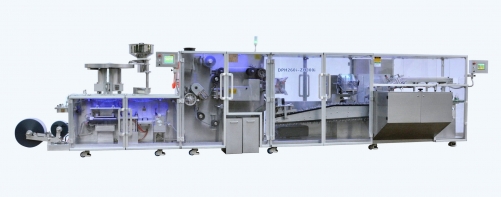

. Adopt various robot feeders for packaging of ampoules, vials, oral liquid, and

Through the integration of a blister and cartoner module for packaging and cartoning of pharmaceutical ampoules, vials, oral liquid, and syringe, etc.

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

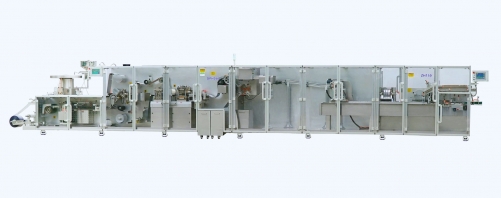

This line integrated a pillow packing unit after the blistering unit, to allow the plastic thermoforming blister package to be sealed again by laminated film that offers a nearly complete barrier for water, light, and oxygen, allowing an extended product

The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and a waste material trimming cutter.

The heart of a Blister Line is the connection between the Blister Machine and Cartoner. In this line, the connection phase is truly innovative thanks to a servo-regulated robot that picks up blister cards and transfers them to the cartoning machine synchr

This line adopts the fully-enclosed structure and safety door, it is in line with the most stringent European safety standards.

After actions of inserting of blister cards and leaflets into cartons, embossing and closing, the cartons were discharged automatically.

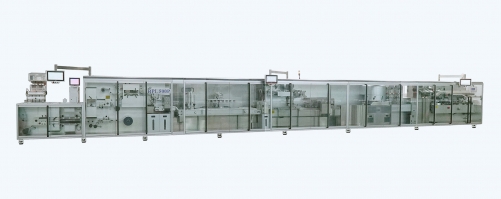

This Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for medium batch production

The blister magazine in the cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted and when they free fall, are then held in position by the transfer belt.

1