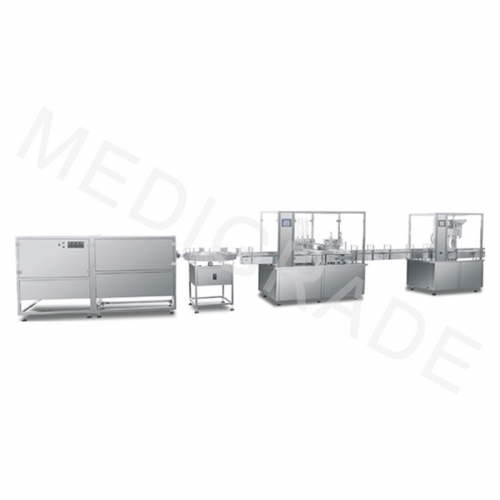

Filling Capping Machine

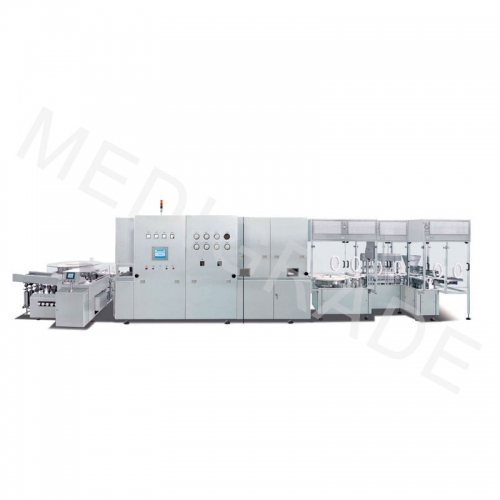

■ This low-speed line is specially designed for the requirement of low output and short-run production with reliable and stable production under the intermittent motion, the major machine parts procured from well-know brand, adopt smart control system. Th

This compact line is specially designed for the requirement of low output and small serial production with various sizes of the container, the major machine

parts procured from well-know brand, adopt smart control system.Th line benefits our

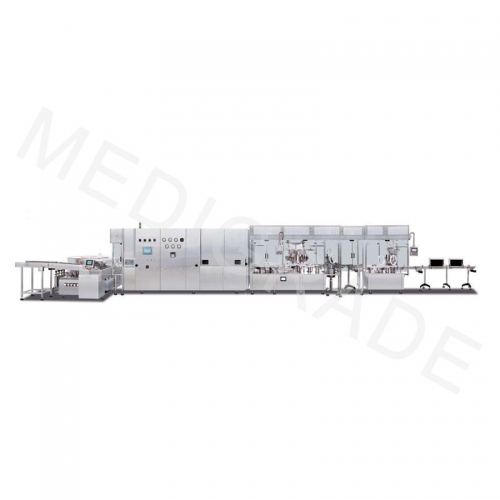

·High-speed linkage line is suitable for high-volume production applications. The entire filling line is stable and reliable in the intermittent operation mode. Its main components are imported first-class brands. The whole line mold is positioned and ins

The servo motor is used to control the number of driving coils of the screw powder feeding, so as to accurately control the raw material powder to be packed into the vial according to the specified capacity, and the rubber stopper is covered.

The servo motor is used to control the number of driving coils of the screw powder feeding, so as to accurately control the raw material powder to be packed into the vial according to the specified capacity, and the rubber stopper is covered.

The servo motor is used to control the number of driving circles of the screw conveying powder, so as to accurately control the raw material powder to be packed into the silverbottle according to the required capacity and cover the rubber stopper tightly.

The machine is a straight line intermittent full servoing filling machine. The large dose solvent bottle enters the synchronous belt through the bottle plate and completes the filling and plugging of the liquid in the process of intermittent transmission,

The machine is a straight line continuous or intermittent full servoing filling machine. The Cilin bottle enters the synchronous belt through the bottle plate and completes the filling and plugging of the liquid in the process of continuous or intermitten

The main working principle is to use the imported microcomputer to control the pulsation frequency of the peristaltic pump, so as to prepare to control the raw material liquid to be filled into the antibiotic glass bottle according to the prescribed filli

This equipment is designed for drying, sterilizing and depyrogenating of different kinds of containers. The sterilizing tunnel could be divided into three different sections (preheating, heating, and cooling). Different customers can choose different conf

The CPH series bottle washer is supplied by the conveyor belt, and the bottle is sent to the water bath for ultrasonic cleaning through evenly distributed ultrasonic pretreatment zone. Then the bottle is conveyed softly to the end of the water bath by sen

The CPH series bottle washing machine is supplied by the conveyor belt, and the bottle is sent to the water bath for ultrasonic cleaning through evenly distributed ultrasonic pretreatment zone. Then the bottle is conveyed softly to the end of the water ba

Suitable for the separation of antibiotic bottle powder or other powder.

The equipment is accurate, micro computer set measurement, accurate and safe without obstacle. Simple operation, high in automation, easy to disassemble and can be cheeked with RABS

It’s applicable to the powder separation and rolling (or spinning) cover of the round bottle. A device realizes the function of split, upper cover and rolling. It’s suitable for the packaging of powder and granules of pharmaceutical factory, food factory.

It's applicable to the packaging of plastic bottles and glass bottles of 20-500ml. It is widely used in large volume liquid packaging such as large infusion and syrup. Increase the filling pump and improve the output.

The HHGG high speed syrup filling machine adopts the straight line type filling, multi head rotating cover mode, and the whole process runs smoothly and improves the output.

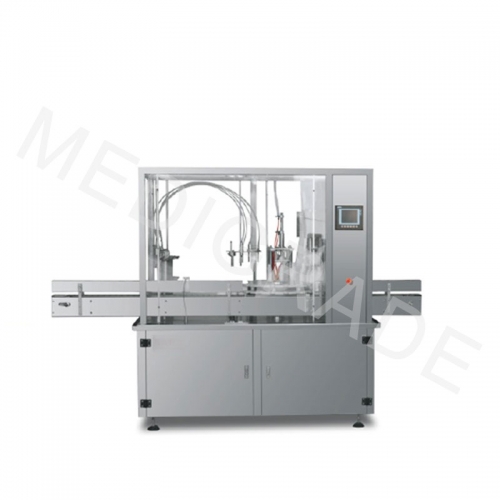

Applicable to the filling sealing of 20-500ml bottle .It is the ideal equipment for liquid filling, and it cannot be filled with foam, no overflow, stable performance and convenient maintenance. Optional dust cover, no bottle filling function.

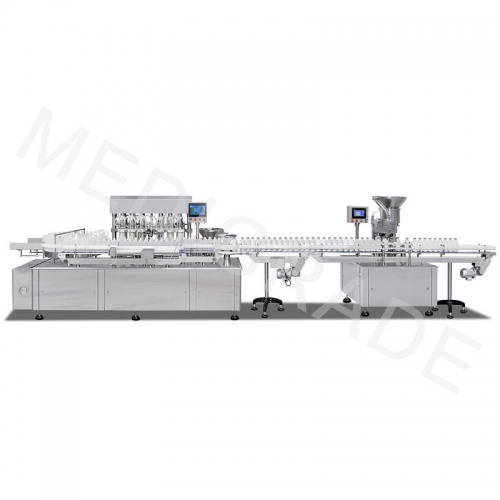

This linkage is formed by HHLP automatic bottle, HNGP bottle machine, hhg-s16 double-track filling machine, hhz-8 high speed rolling mill. The linkage line is suitable for full-automatic production of large-capacity vaccines, can be realized from 50-500ml