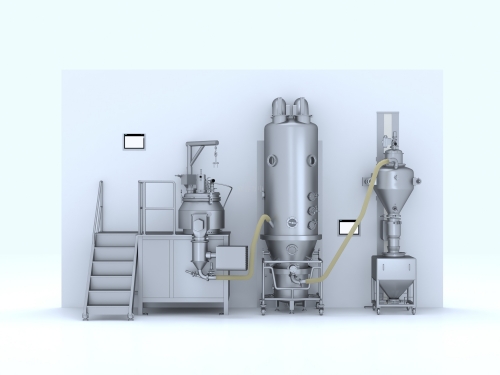

Closed granulation line

Brief introduction

The Closed granulation line is mainly used in the powder granules of the pharmaceutical,food,chemical and other industries,which can inhibit the dust leakage and pollution generated during the process of material transfer,posing a threat to people and the

Description

Customer Case

Featured Products

The Closed granulation line is mainly used in the powder granules of the pharmaceutical,food,chemical and other industries,which can inhibit the dust leakage and pollution generated during the process of material transfer,posing a threat to people and the envirgnment.The closed conveying method ensures that the conveying eficiency of granulation,drying and granulation process is more scientific and reasonable,reduces the space occupied by the equipment,and makes the production procesa more applicable to the GMP requirements.

- Features:fully automated and inteligent

- ATEX

- Production capacity:15-200(kg/batch)

- Suitable applications:Pharmaceutical, food, chemical

Detailed introduction

Working principleProcess control

Based on advanced industrial tablet computer automation control,it provides complete process control and various parameter control,including graphical operation interface,online monitoring,trend chart,recipe processing,batch management, barcode processing,CIP control,and self-diagnosis processing.The management system is fully compatible according to industry standard communication network protocol control strategy and factory-wide monitoring system.

Process analysis

FDA'S PAT(Process Analysis Technology)combines the design capabilities of its equipment with process engineering expertise to integrate an online(PAT)analyzer into the system to provide a true understanding of the process and help customers achieve key product quality objective so that you can actively control the key quality characteristics of your product.

Closed control

The unique Closed control consists of integrating stable sealing technology into a complete solution for pharmaceutical solids facilities,closely monitoring the quality and GMP standards applied to the customer's site,providing customized and efficient solutions for a wide range of specifications and complex projects.

Safety and environment

In order to fully comply with national and local regulations,for emission control,as well as the recycling the solvent,the exit filter and the fuly enclosed equipment can be provided as needed according to the explosion-proof and anti-pressure standards.

Features

1.The Closed granulation line fully considers the compatibility of the equipment between the systems.According to the actual production capacity and dosage form design of the user,the production capacity of the whole processes can be optimally configured to ensure the continuity and stability of production.By the industrial tablet computer,automation control system can store,collect and print the process data separately,centraly control the parameter setting and monitoring of multiple devices,reflect the working status,data statistics and fault self-diagnosis in real time,making the process more stable,fully automated and inteligent.

2.The equipment can be operated independently or controlled by system to realize the optimal parameterized process control of the equipment,reducing the pause and dwell time,and the inteligent cooperation of the equipment makes the granulation process optimal,thus obtaining efficient granulation yield and consistency.so that CIP cleaning can be reliably guaranteed.

Technical parameter

| Item model | 60 | 120 | 200 |

| Production capacity(kg/batch) | 15-60 | 50-120 | 120-200 |

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for resea

The machine is mainly used for online cleaning of equipment in the production process of solid preparations,used together with equipment such as fluid bed machine,coating machine and wet mixing granulator,It is also sulitable for the cleaning of industria

With compact structure, convenient operation, good sealing performance and high adaptability, the moveable cleaning station produced by our company is used for cleaning industrial equipment and other parts that require cleaning in such industries as medic