Non pvc iV bag forming,filling,and sealing

Brief introduction

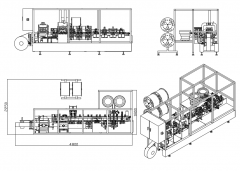

The machine is designed for pharmaceutical use according to the GMP and FDA guidelines. It is designed for forming, filling and sealing bags.

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach

Description

Customer Case

Featured Products

SSM series of Non PVC film soft bag infusion IV solution production line is a more advanced technology China domestic and abroad, which integrates efficiency of the new production line, the existing soft bag production line is the upgrading of products, can automatically finish printing, bag making, filling and sealing process.

Compared with domestic similar machinery, it has the following significant advantages:

1. High production efficiency, good stability, low failure rate.

2. The length of the production line is compressed by 1/3, and the workshop area and air conditioning purification area are reduced by 1/3, thus greatly reducing the investment and use cost.

3. 99.99% utilization rate of packaging materials to reduce the loss of energy resources.

4. Simplified production line structure, more stable and reliable performance, such as minus the bag handover

The process greatly improves the reliability of the production line.

Main features

- Advanced equipment technology, unique and reasonable structure, stable and reliable performance.

- The machine has strong storage and memory function, for different packaging materials, users can store the actual welding parameters in advance, and can directly call when changing packaging materials.

- The filling system adopts Koch mass flow meter, high filling accuracy, wide filling range, and can realize automatic in-place cleaning/in-place disinfection (CIP/SIP).

- Unique structure, high production efficiency, can produce 7500 more per hour, single chamber soft bag.

- The production line is an all-in-one bag filling machine, the length is reduced by 1/3, the workshop area and air conditioning purification area are reduced by 1/3, so that the investment and use cost are greatly reduced.

Main parameter

| Model | SSM1A/1200 | SSM2A/2500 | SSM4A/5000 | SSM6A/7500 | |

| Production capacity | 1200 bag/hour | 2500 bag/hour | 5000 bag/hour | 7500 bag/hour | |

| Bag specifications | 50ml,100ml,250ml,500ml | ||||

| Number of bags per time | 1 | 2 | 4 | 6 | |

| Interface form | Boat port | Boat port | Boat port | Boat port | |

| Ribbon size | The standard ribbon with an inner diameter of 3 inches and an outer diameter of less than 140mm is generally available on the market | ||||

| Film roll size | The standard ribbon with an inner diameter of 6 inches and an outer diameter of no more than 600mm is available on the market | ||||

| Printed form | Hot plate hot stamping, monochrome; Production date, validity period, approval number printed at the same time and easy to replace reliable | ||||

| Power supply | 3 Phases 380V 50HZ | ||||

| Power | 8KW | 22KW | 30KW | 32KW | |

| Compressed air pressure | Higher than 0.6Mpa, dry and oil-free compressed air, cleanliness is 5μm, when the pressure is too low, the machine will automatically stop and alarm | ||||

| Compressed air consumption | 1000L/min | 2000L/min | 3000L/min | 4000L/min | |

| Clean air pressure | Clean compressed air higher than 0.4Mpa and cleanliness 0.22μm | ||||

| Clean air consumption | 500L/min | 800L/min | 1000L/min | 1200L/min | |

| Cooling water consumption | 100L/h | 150L/h | 300L/h | 400L/h | |

| Equipment size | 4.2m×2.1m×2.1m | 5.6m×2.1m×2.1m | 8.5m×2.7m×2.1m | 9.9m×2.55m×2.1m | |

| Equipment weight | 3.5T | 6T | 10T | 10T | |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

The machine is designed for pharmaceutical use according to the GMP and FDA guidelines. It is designed for forming, filling and sealing bags.

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach