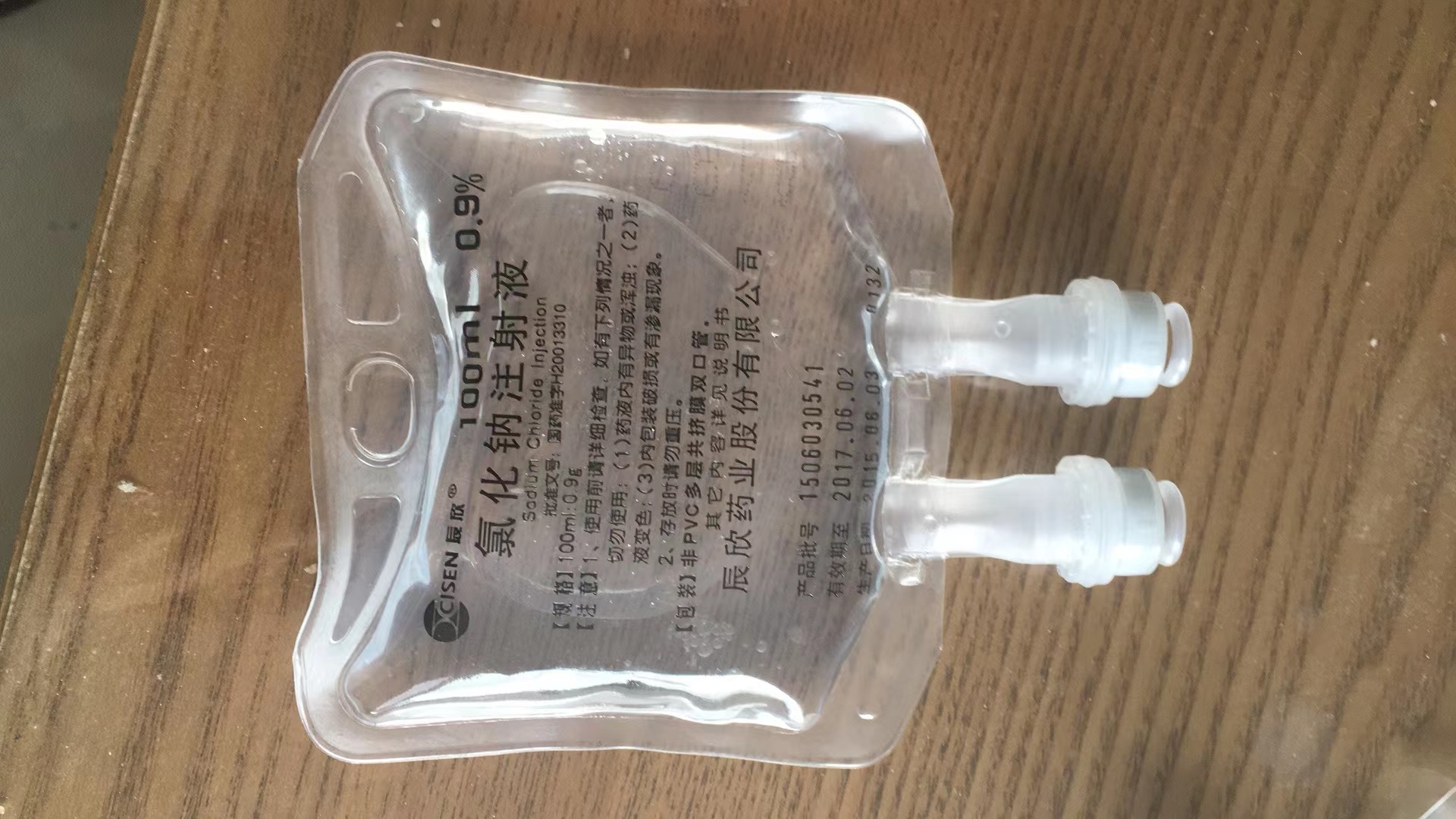

Non-pvc infusion bag making machine

Brief introduction

The machine is designed for pharmaceutical use according to the GMP and FDA guidelines. It is designed for forming, filling and sealing bags.

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach

Description

Customer Case

Featured Products

Machine parameter

| Equipments specification | Length (Max. Mm) |

Width (Max. Mm) |

Heigth (Max. Mm) |

Remark | ||

| SSM2000 |

3700 (including roller’s length ) | 2000 |

1800 | 2 bags/group | ||

| Layout | For SSM2000 type equipment, pls refer to Figure 1 attached. | |||||

| Equipments capability | ||||||

| Type | SSM2000 | Remark | ||||

| 100ml | 2500B/H | Conpressed air 0.65Mpa | ||||

| 250ml | 2500B/H | |||||

| 500ml | 2200B/H | |||||

| 750ml | 2200B/H | |||||

| 1000ml | 2000B/H | |||||

| Pass Rate | ||||||

| Pass Rate | Min. 99.97% (based on the qualified materials and non error operation) | |||||

| Waste edge remove rate | 99.99% there are collection container | |||||

| Energy demand | ||||||

| Power | 3Phases 380V 50Hz SSM2000 Max. 12kw |

|||||

| Conpressed Air | 0.5Mpa~0.75Mpa, SSM2000 1800L/min |

|||||

| Working Environment | ||||||

| Room Tempreture | 20 °C – 24 °C | |||||

| Air Humidity | 45%-65% Max.85% |

|||||

| Noise | Max. 75dB | |||||

| Operator | Fixed operator : 1 person Auxiliary operator : 1~2 persons (to replace production materials) |

|||||

| Language | Chinese&English | |||||

SSM2000 M2 Device layout diagram

Automatically machine functions

- Brief introduction

According to its required capacity, the machine is either equipped with one working stations.

The machine’s framework consist of stainless steel AISI 304, especially suitable for pharmaceutical use.

All components coming in touch with the product are made of stainless steel AISI 316 L quality.

The safety doors and windows mounted on the framework are made of polycarbonate. Thus they correspond to the health and safety regulations and ensure at the same time an optical supervisory control.

The machine is equipped with a switch cabinet and a control unit. The control units are interconnected via a bus system.

Two operators are necessary to operate the machine (1 permanent, second operator only necessary for film change).

The machine consists of the following components:

-01-Unwinding station

-02-Printing station

-03-Film transfer station

-04-Contour welding and cutting station

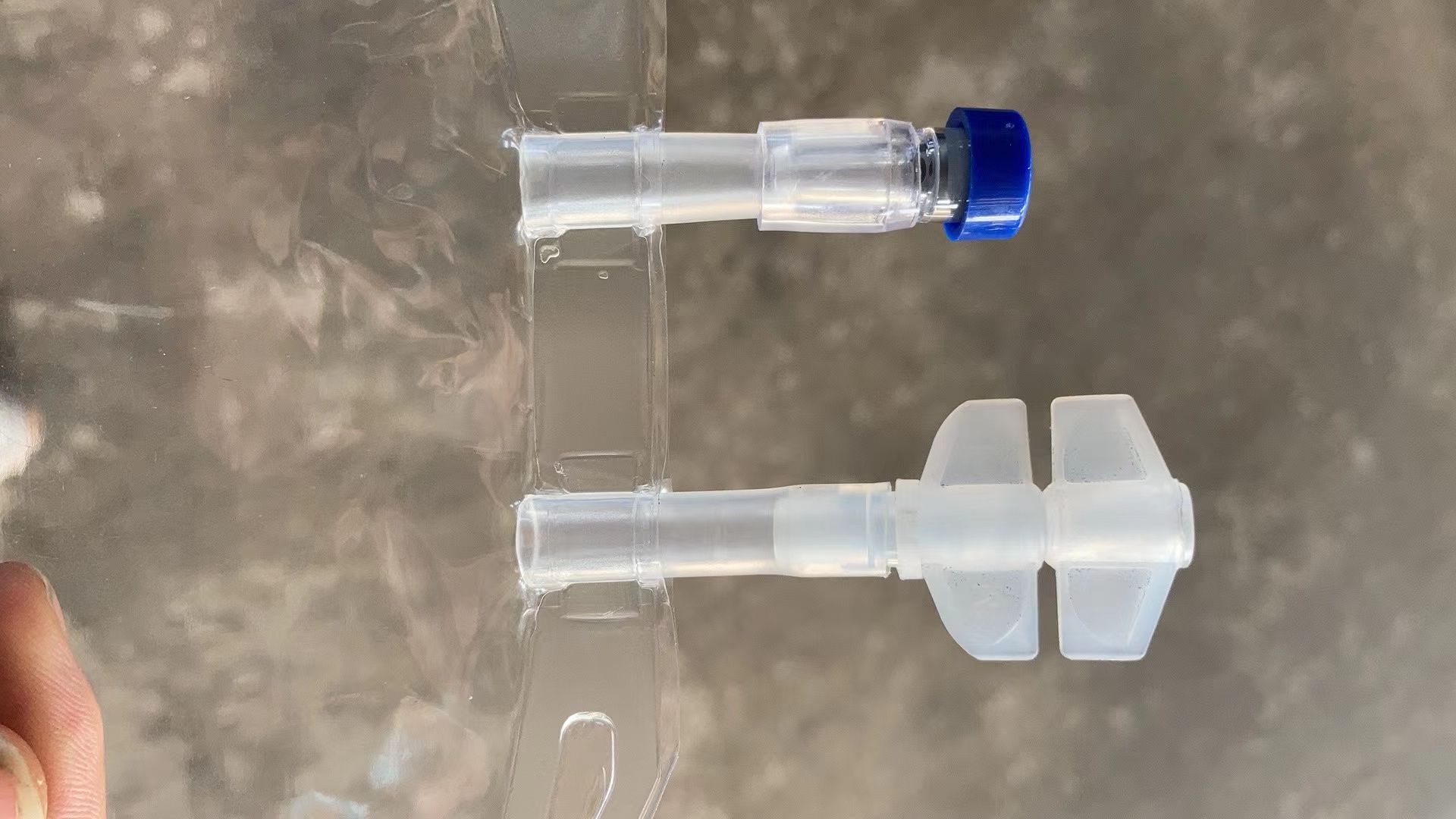

-05-Port Cutting

-06-Port pre heating station

-07-Port welding station

-08-Waste ejector station

-09-Bag outfeed with transport belt

2、Station that

2.1 Unwinding station

The film is fed into the machine via a motor controlled unwinding device. The film roll is pneumatically cramped onto the reception bolt. In order to ensure a constant film transfer speed, the film is temporarily stored on a castoring wheel. Thus, the changing film roll diameter is compensated.

Membrane-free alarm,alarm can be exhausted in the membrane.*

2.2 Printing station

The 'Full-Face' print is printed on the bag film using a hot film printing unit.

Variable manufacturing data, such as the production number, the best-before date, the batch number, etc. are adapted by exchanging the separate reception vises which are especially designed for this purpose.

Printing temperature, printing time and printing pressure are adjustable.

The automatic printing film supervisory unit (odometer to determine the film feed) ensures a machine stop in case the printing film has run out or teared off, and thus ensures a constant bag printing.

The printing film reception rolls are equipped with a pneumatic, hand-operated clamping. So the printing film can be exchanged very easily and without any special tool, the time required for service purposes is reduced to a minimum.

In order to ensure that the bag film does not adhere to the printing film subsequent to the printing process, the bag film is held down by pneumatic film clips.

For changing the printing block, only two clamps have to be released. The block reception must not be removed if you have to change the characters of the production and best-before date, the batch number, etc.

2.3 Film transfer station

Film transfer with film opener.

The film transfer is performed by an electric motor driven linear gear unit. During the transfer, the film is held by pneumatic film clips. When the film is fed in, the two film layers are opened with a fixed opener taper key in the front area, where the next step, i.e. the port insertion, will be carried out.

2.4 Contour welding and cutting station

This station is used for welding the outer contour of the bag, for adhering the ports to the bag film and for cutting the outer contour of the bags. The welding is done by exchangeable welding tools provided with heating cartridges to produce the required welding temperature.

Welding time, pressure and temperature are adjustable.

The welding temperature is verified within a defined min./max. range by the PLC control unit and temperature sensor, in order to ensure a permanently correct welding process.

In case the welding temperature remains under or exceeds – for any reason whatsoever – the defined min. / max. range, the machine will stop. Simultaneously, an error message is displayed in the control panel.

Using the unique design of the heating plate and mold separation, replacement of mold is extremely simple.

2.5 Tube cutting

2.6 Tube pre heating station

This station serves for pre-heating the ports up to a certain temperature before they arrive between the two bag film layers of the contour welding station, and thus it ensures an optimal welding of port and bag film. For this, two pre-heating tools which are pre-heated to a certain temperature and having the same contour as the ports, are brought together on the port. Pre-heating temperature and time can be adjusted via the control panel.

2.7 Port welding station

This station is used for welding ports and bag film.

For this, two welding tools which are preheated up to a certain temperature are brought together on the bag head contour.

Welding time and temperature are adjustable via control panel.

Using the unique design of the heating plate and mold separation, replacement of mold is extremely simple.

High-precision processing technology, perfect welding.

2.9 Bag outfeed with transport belt

The finished bags are taken out by gripper system and leave the machine to the outfeed conveyor belt.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

The machine is designed for pharmaceutical use according to the GMP and FDA guidelines. It is designed for forming, filling and sealing bags.

The machine is designed as a single-track linear system with a motor actuated film transfer control. In the mach