Sterile production microjet homogenizer

Brief introduction

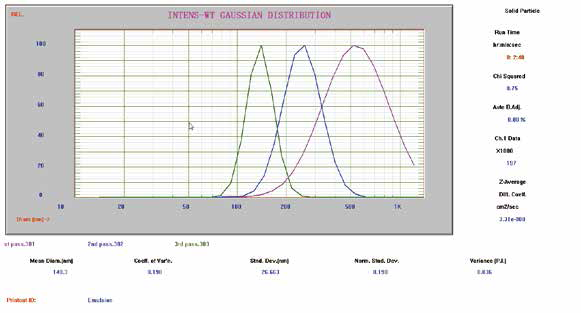

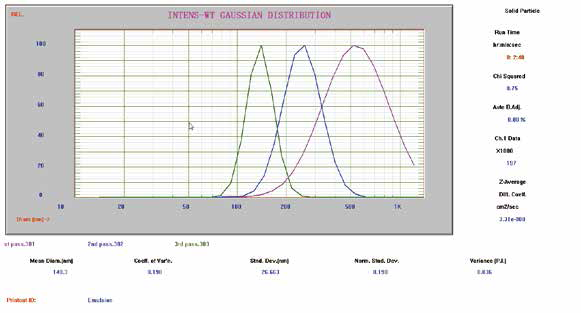

The material flow through a one way valve, was pressured in the high pressure chamber. when pass the

micron noozle, the material will subsonic impact the chamber, with a shearing effect at the same time, then

get a narrow range of micron particle.

micron noozle, the material will subsonic impact the chamber, with a shearing effect at the same time, then

get a narrow range of micron particle.

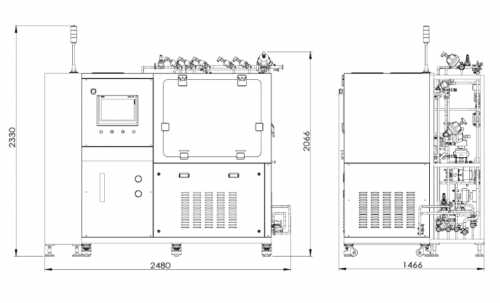

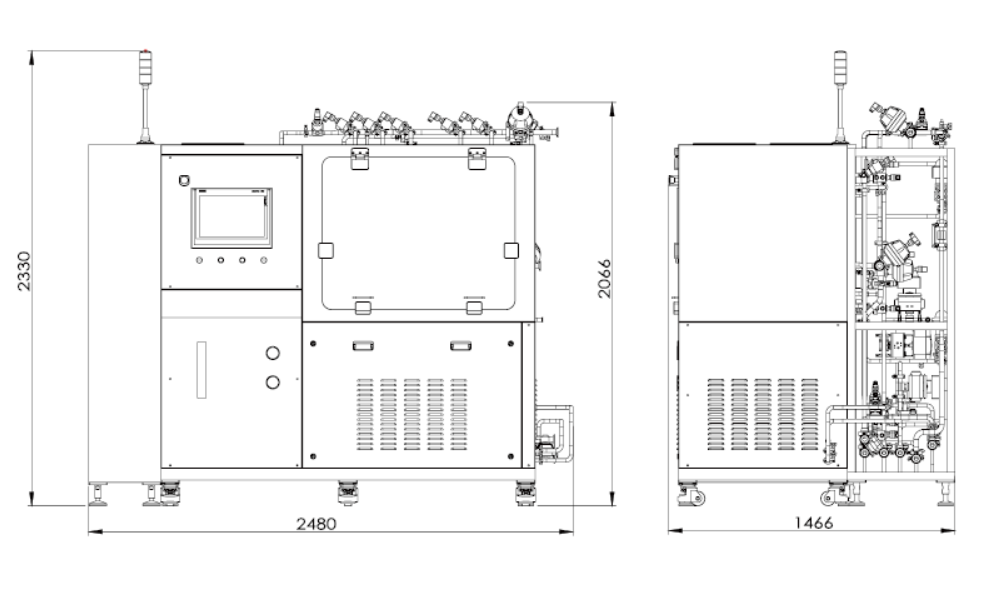

Description

Customer Case

Featured Products

Product Advantage

Modular high-pressure design, can achieve 24-hour continuous operation

PLC automatic control, in accordance with GAMP specifications

Control system complies with FDA 21 CFR Part 11

Sterile process design, in line with cGMP, automatic CIP / SIP, can meet

the production of sterile preparations

Applicable for high viscosity medium, resistant to organic solvents and

excellent chemical resistance

Explosion-proof design for usage in explosive environment(Ⅰ/Ⅱ)

Both Noozle and Impinging Stream Chamber available

Working Principle:

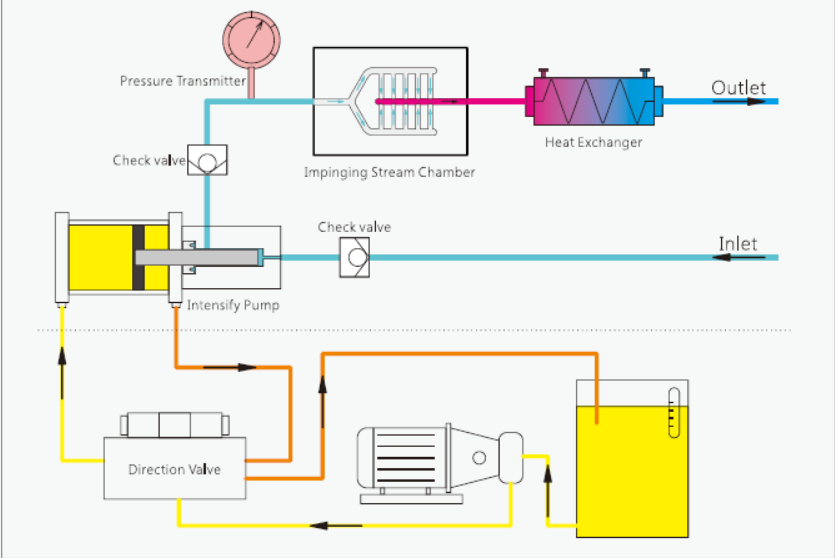

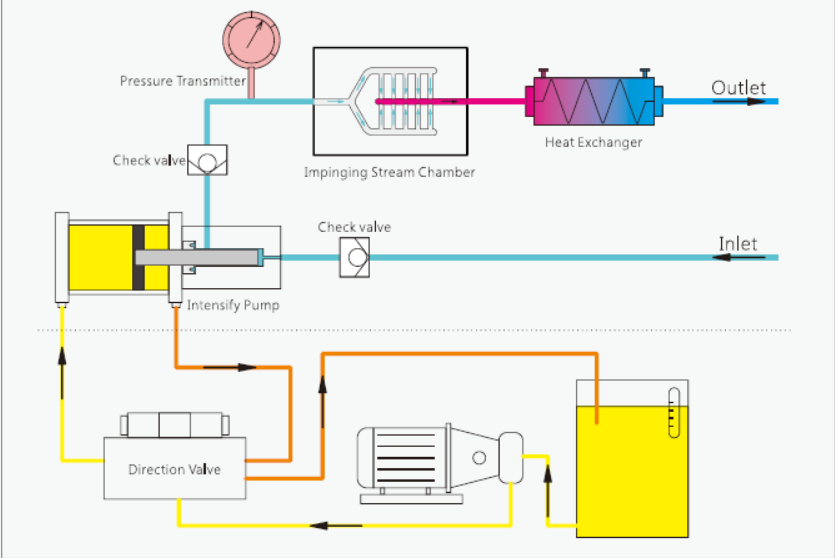

When liquid goes through the one way valve, it will be pressured in the chamber. the plunger push the liquid pass the diamond nozzle. Then the liquid was combined with kinetic energy. three actions will arise: impact the chamber wall, explosion to high shearing, liquid impacted each other. Then the ingredients' size will be decreased. After recycle several times, then can achieve the required particle size.

Advantages;

Electric- liquid controlled movement. With the safety condition, special designed chamber, can achieve the pressure max in 30000psi, ensure the efficiency for nano scale shearing. Can be recycled homogenizing.

Nozzle: the core material of Nozzle is diamond. The sealing design is tapered.it can keep the sealing efficiency in long life with super high pressure.

Cooling system: the machine was connected with chilling water, can control the liquid temperature at required level -20℃---50℃。

Applications

Fat emulsion, liposome emulsion, nanoscale suspension,

Cell rupture

Food, cosmetic's homogenizing.

New energy product (graphene battery slurry, solar panel slurry

TECHNICAL PARAMETERS

APPLICATION AND PRINCIPLE

Main Application

Pharmaceutical Industry

◎ Homogenization of drug-loaded emulsion

◎ Nano particle preparation of liposome

◎ Dispersion of Nano suspension

New Materials Industry

◎ Dispersion of graphene conductive additives

Food Industry

Electronic Paste Industry

Cosmetics Industry

◎ Homogenization of lipsome granules

Working Principle

The material flow through a one way valve, was pressured in the high pressure chamber. when pass the

micron noozle, the material will subsonic impact the chamber, with a shearing effect at the same time, then

get a narrow range of micron particle.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Modular high-pressure design, can achieve 24-hour continuous operation

PLC automatic control, in accordance with GAMP specifications

Control system complies with FDA 21 CFR Part 11

Sterile process design, in line with cGMP, automatic CIP / SIP, can meet

the production of sterile preparations

Applicable for high viscosity medium, resistant to organic solvents and

excellent chemical resistance

Explosion-proof design for usage in explosive environment(Ⅰ/Ⅱ)

Both Noozle and Impinging Stream Chamber available

Working Principle:

When liquid goes through the one way valve, it will be pressured in the chamber. the plunger push the liquid pass the diamond nozzle. Then the liquid was combined with kinetic energy. three actions will arise: impact the chamber wall, explosion to high shearing, liquid impacted each other. Then the ingredients' size will be decreased. After recycle several times, then can achieve the required particle size.

Advantages;

Electric- liquid controlled movement. With the safety condition, special designed chamber, can achieve the pressure max in 30000psi, ensure the efficiency for nano scale shearing. Can be recycled homogenizing.

Nozzle: the core material of Nozzle is diamond. The sealing design is tapered.it can keep the sealing efficiency in long life with super high pressure.

Cooling system: the machine was connected with chilling water, can control the liquid temperature at required level -20℃---50℃。

Applications

Fat emulsion, liposome emulsion, nanoscale suspension,

Cell rupture

Food, cosmetic's homogenizing.

New energy product (graphene battery slurry, solar panel slurry

TECHNICAL PARAMETERS

| 2000 Aseptic type |

|

| Pressure Range | (Up to)30,000psi |

| Capacity | 330ml/min |

| Minimum Capacity | 50ml |

| Weight | 250kg |

APPLICATION AND PRINCIPLE

Main Application

Pharmaceutical Industry

◎ Homogenization of drug-loaded emulsion

◎ Nano particle preparation of liposome

◎ Dispersion of Nano suspension

New Materials Industry

◎ Dispersion of graphene conductive additives

Food Industry

Electronic Paste Industry

Cosmetics Industry

◎ Homogenization of lipsome granules

Working Principle

The material flow through a one way valve, was pressured in the high pressure chamber. when pass the

micron noozle, the material will subsonic impact the chamber, with a shearing effect at the same time, then

get a narrow range of micron particle.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

The material flow through a one way valve, was pressured in the high pressure chamber. when pass the

micron noozle, the material will subsonic impact the chamber, with a shearing effect at the same time, then

get a narrow range of micron particle.

Modular high-pressure design, can achieve 24-hour continuous operation

PLC automatic control, in accordance with GAMP specifications

Control system complies with FDA 21 CFR Part 11

Sterile process design, in line with cGMP, automatic CIP / SIP, can mee