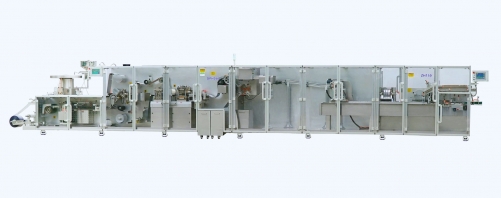

Blister Line DPH260H3-ZH150

Brief introduction

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

Description

Customer Case

Featured Products

Different packaging materials and principles of forming, Blister packs may be divided into mainly two types: aluminum/plastic (thermoforming) blister pack and aluminum/aluminum (cold forming) blister pack.

The advantages of thermoforming blister pack:

> It can visually examine the product through the transparent plastic, it is easy to reject the fault blister card both by inspecting the camera or naked eyes.

> The most basic material for the forming web is PVC, it is low cost and has the ease of thermoforming.

> Because the cavity or pocket contains the item snugly so it can adopt a universal feeder, it is low cost and easy of operation.

The disadvantages of thermoforming blister pack:

> The poor protective properties because of poor barrier against moisture ingress and oxygen ingress;

The advantages of cold forming blister pack:

> The use of aluminum offers a nearly complete barrier for water, light, and oxygen, allowing an extended product expiration date.

The disadvantages of cold forming blister pack are:

> The slower speed of production compared to thermoforming;

> The lack of transparency of the package increase the difficulty for inspecting system to reject the fault blister card;

> The larger size of the blister card (aluminum cannot be formed with near 90 degree angles), increase the cost.

> The material of forming aluminum film is more expensive than PVC.

> Because the cavity or pocket is larger than the item so the feeder should be dedicated, which increases the cost and operation difficulty.

To take the above advantage and get rid of the disadvantage, this industry launched the third type of blister pack: aluminum/plastic/aluminum blister pack.

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

Because the item is filled in thermoforming pocket or cavity so it can adopt a universal feeder, it is low cost and easy to operate.

The inspecting camera can detect the fault blister card easily because of the transparency of thermoforming plastic.

The tropical aluminum has the same property as cold-forming aluminum that can offer a nearly complete barrier for water, light, and oxygen, perfectly protect the medicine.

The characteristics of Blister Packaging Line

> The alu/PVC unit adopts larger forming area stating and rotary style sealing stating thus increase the speed.

> The tropical alu forming station has a larger forming area archive larger output requirement.

> The second sealing station has a larger sealing area to allow the plastic thermoforming blister package to be sealed with formed tropical alu at higher output capacity.

> The punch station can adopt the crossing type; the trimming waste is about 1mm between two blisters; it can save more material.

> Thanks to rotary sealing style (alu-PVC) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can go up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).

> The Caroning Machine is intermittent style, but thanks to its rotary cartons pick-up device and continuous motion blister conveyor chain, the machine can runs at a higher speed than the traditional cartoning machine.

> Adopt a long carton magazine.

Gallery

The PVC thermoforming station

Because the item is filled in thermoforming pocket so it can adopt universal or vibratory feeder, it is low cost and ease of operation

While alu/pvc sealing and embossing the tropical alu is transferred to tropical alu forming station

The tropical alu forming station has larger forming area archive larger output requirement

There are two waste tanks collect waste material alternatively

The punch station can adopts the crossing type, the trimming waste is about 1mm between two blisters; it can save more material

Inside the magazine, the blister cards are counted when they free fall via the servo-motor, and are then held in position by the transfer belt.

The Leaflet are isolated from the bottom from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand

The rotary carton pick-up suck the cartons from the carton magazine

The inserter device can push the blister cards and leaflet into the carton.

The rotary carton pick-up suck the cartons from the carton magazine then places them in carton conveyor chain

Long carton magazine

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment

After actions of inserting of blister cards and leaflets into cartons, embossing and closing, the cartons were discharged automatically

Main Technical Parameters

DPH260H3

ZH150

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

The advantages of thermoforming blister pack:

> It can visually examine the product through the transparent plastic, it is easy to reject the fault blister card both by inspecting the camera or naked eyes.

> The most basic material for the forming web is PVC, it is low cost and has the ease of thermoforming.

> Because the cavity or pocket contains the item snugly so it can adopt a universal feeder, it is low cost and easy of operation.

The disadvantages of thermoforming blister pack:

> The poor protective properties because of poor barrier against moisture ingress and oxygen ingress;

The advantages of cold forming blister pack:

> The use of aluminum offers a nearly complete barrier for water, light, and oxygen, allowing an extended product expiration date.

The disadvantages of cold forming blister pack are:

> The slower speed of production compared to thermoforming;

> The lack of transparency of the package increase the difficulty for inspecting system to reject the fault blister card;

> The larger size of the blister card (aluminum cannot be formed with near 90 degree angles), increase the cost.

> The material of forming aluminum film is more expensive than PVC.

> Because the cavity or pocket is larger than the item so the feeder should be dedicated, which increases the cost and operation difficulty.

To take the above advantage and get rid of the disadvantage, this industry launched the third type of blister pack: aluminum/plastic/aluminum blister pack.

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

Because the item is filled in thermoforming pocket or cavity so it can adopt a universal feeder, it is low cost and easy to operate.

The inspecting camera can detect the fault blister card easily because of the transparency of thermoforming plastic.

The tropical aluminum has the same property as cold-forming aluminum that can offer a nearly complete barrier for water, light, and oxygen, perfectly protect the medicine.

The characteristics of Blister Packaging Line

> The alu/PVC unit adopts larger forming area stating and rotary style sealing stating thus increase the speed.

> The tropical alu forming station has a larger forming area archive larger output requirement.

> The second sealing station has a larger sealing area to allow the plastic thermoforming blister package to be sealed with formed tropical alu at higher output capacity.

> The punch station can adopt the crossing type; the trimming waste is about 1mm between two blisters; it can save more material.

> Thanks to rotary sealing style (alu-PVC) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can go up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).

> The Caroning Machine is intermittent style, but thanks to its rotary cartons pick-up device and continuous motion blister conveyor chain, the machine can runs at a higher speed than the traditional cartoning machine.

> Adopt a long carton magazine.

Gallery

The PVC thermoforming station

Because the item is filled in thermoforming pocket so it can adopt universal or vibratory feeder, it is low cost and ease of operation

While alu/pvc sealing and embossing the tropical alu is transferred to tropical alu forming station

The tropical alu forming station has larger forming area archive larger output requirement

There are two waste tanks collect waste material alternatively

The punch station can adopts the crossing type, the trimming waste is about 1mm between two blisters; it can save more material

Inside the magazine, the blister cards are counted when they free fall via the servo-motor, and are then held in position by the transfer belt.

The Leaflet are isolated from the bottom from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand

The rotary carton pick-up suck the cartons from the carton magazine

The inserter device can push the blister cards and leaflet into the carton.

The rotary carton pick-up suck the cartons from the carton magazine then places them in carton conveyor chain

Long carton magazine

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment

After actions of inserting of blister cards and leaflets into cartons, embossing and closing, the cartons were discharged automatically

Main Technical Parameters

DPH260H3

| Max. Speed: | alu/pvc/alu 105 punches/min. |

| Max Forming Depth: | 12mm |

| Material: | Max. width 265mm |

| Machine Power: | 25kw |

| Machine Dimension: | 7000×1300×2000mm |

| Machine Weight: | 4500kg |

ZH150

| Max.Output: | 150 cartons/min. |

| Range of Carton Size: | Max.150x115x50mm Min.75x30x15mm |

| Machine Power: | 1.8kw |

| Machine Dimension: | 3500x1500x1800mm |

| Machine Weight: | 1500kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.