Description

Customer Case

Featured Products

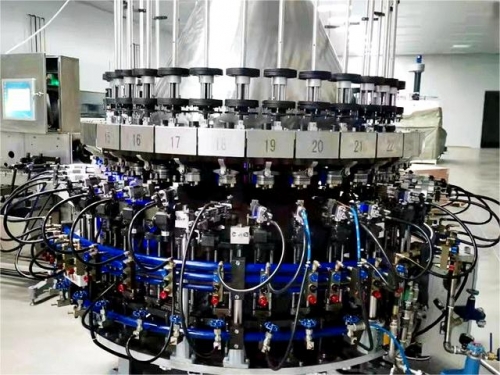

Tubular Glass Vial Making Machine:

It can produce the international general atandard ampoule , can satisfy both at home and abrosd to the shape of the ampoule, using performance and packing requirement, this production line is the development direction of ampoule production in our country, is in the national drug administration as one of the main euipment of the ampoule prodution in the future.

Import the prodution line,after many years of production, the user's feedback,gradually reached a high degree of automation. Compact structure, high output. the layout is reasonable, the tube from raw material to the finished product into line,an bottle quality to meet internatioanal atandards and less energy consumption,low noise, low labor intensity of workes, is the medical glass ampoule production of a kind of sdeal equipment in the future.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

It can produce the international general atandard ampoule , can satisfy both at home and abrosd to the shape of the ampoule, using performance and packing requirement, this production line is the development direction of ampoule production in our country, is in the national drug administration as one of the main euipment of the ampoule prodution in the future.

Import the prodution line,after many years of production, the user's feedback,gradually reached a high degree of automation. Compact structure, high output. the layout is reasonable, the tube from raw material to the finished product into line,an bottle quality to meet internatioanal atandards and less energy consumption,low noise, low labor intensity of workes, is the medical glass ampoule production of a kind of sdeal equipment in the future.

| 1~3ml | 1.2.3ml can compatibility on one set machine | |||

| Output Speed | Natural gas | Liquefied gas | Air | Total Power |

| 12000PCS/hour | 100m3/hour | 60kg/hour | 10m3/hour | 2.2kw |

| Gas pressure | Oxygen pressure | Air pressure | Weight | Dimension |

| 18Kpa | 30Kpa | 24Kpa | 3500kg | Refer to the layout drawing |

| 5/10ml | 5 and 10 ml can compatibility on one set machine | |||

| Output Speed | Natural gas | Liquefied gas | Air | Total Power |

| 8750Pcs/hour | 100m3/hour | 80kg/hour | 16.25m3/hour | 2.2kw |

| Gas pressure | Oxygen pressure | Air pressure | Weight | Dimension |

| 18Kpa | 30Kpa | 24Kpa | 3750kg | Refer to the layout |

| 20ml | 20 ml can compatibility on one set machine | |||

| Output Speed | Natural gas | Liquefied gas | Air | Total Power |

| 6250Pcs/hour | 150 m3/hour | 100kg/hour | 26.25m3/hour | 2.2kw |

| Gas pressure | Oxygen pressure | Air pressure | Weight | Dimension |

| 18Kpa | 30Kpa | 24Kpa | 3750kg | Refer to the layou |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case