Sterile isolator aseptic negative pressure isolator

Brief introduction

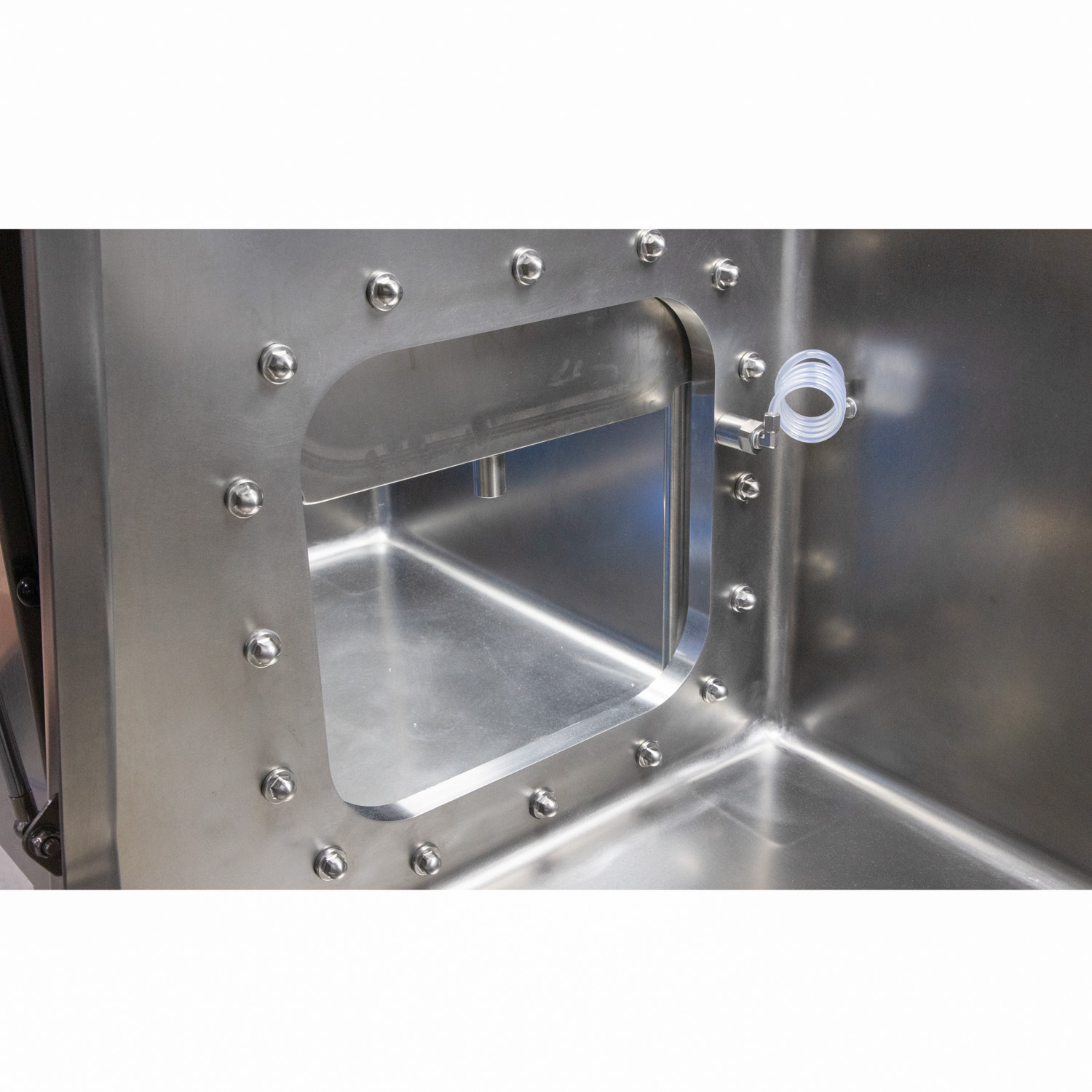

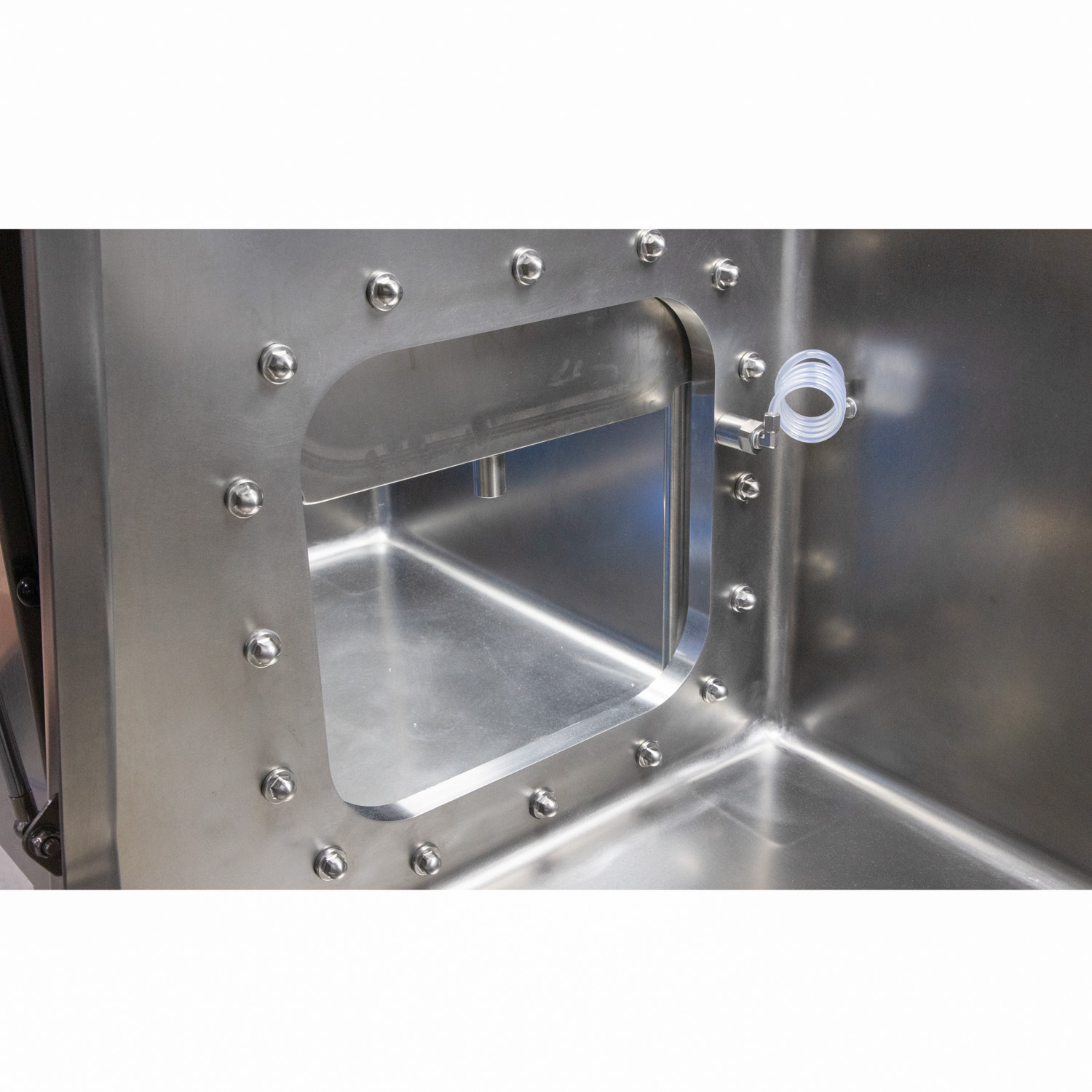

The hard cabin laminar flow type aseptic isolator is a hard-walled structure composed of stainless steel and tempered glass, and the internal environment is dynamic A-level. Use gloves for operation. The gloves can be thickened and anti-breakage or thin a

Description

Customer Case

Featured Products

Product Description

The hard cabin laminar flow type aseptic isolator is a hard-walled structure composed of stainless steel and tempered glass, and the internal environment is dynamic A-level. Use gloves for operation. The gloves can be thickened and anti-breakage or thin and high-feeling; the system is equipped with a Siemens logic controller (PLC) for fully automatic control of pressure and air flow, and has a pressure loss alarm function. Industrial-grade tablet computer control meets the verification requirements of the 2010 version of the GMP computer system.

Performance characteristics

1. Dry vaporized hydrogen peroxide (VHPS*) sterilization, reaching the 6-log spore killing level, with the function of monitoring and controlling the concentration of hydrogen peroxide;

2. The interior of the cabin is cleaned by manual wiping, and there is no dead angle;

3. The VHPS concentration in the cabin after ventilation is less than 1ppm, which can meet the VHPS residual concentration detection;

4. After sterilization, the cabin body is in full compliance with GMPA level cleanliness standards, and online dust particles and planktonic bacteria sampling systems can be integrated and installed;

5. The cabin body pressure reduction test, under 2 times the test pressure, the hourly volume leakage rate is less than 0.5%; it has a leakage alarm function;

6. The isolator can be adjusted according to the needs of use-80pa~80pa, the normal product maintains 40pa~60pa during aseptic operation, the pressure is maintained to the set value ±5pa under static conditions, and the two modes of positive pressure and negative pressure can be preset and stored , Adjust according to demand;

7. The system design meets the requirements of GMP, 2015 Pharmacopoeia, USP/EP, and the control system can meet the 21CFR part11 electronic signature and electronic record requirements;

Specification

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

The hard cabin laminar flow type aseptic isolator is a hard-walled structure composed of stainless steel and tempered glass, and the internal environment is dynamic A-level. Use gloves for operation. The gloves can be thickened and anti-breakage or thin and high-feeling; the system is equipped with a Siemens logic controller (PLC) for fully automatic control of pressure and air flow, and has a pressure loss alarm function. Industrial-grade tablet computer control meets the verification requirements of the 2010 version of the GMP computer system.

Performance characteristics

1. Dry vaporized hydrogen peroxide (VHPS*) sterilization, reaching the 6-log spore killing level, with the function of monitoring and controlling the concentration of hydrogen peroxide;

2. The interior of the cabin is cleaned by manual wiping, and there is no dead angle;

3. The VHPS concentration in the cabin after ventilation is less than 1ppm, which can meet the VHPS residual concentration detection;

4. After sterilization, the cabin body is in full compliance with GMPA level cleanliness standards, and online dust particles and planktonic bacteria sampling systems can be integrated and installed;

5. The cabin body pressure reduction test, under 2 times the test pressure, the hourly volume leakage rate is less than 0.5%; it has a leakage alarm function;

6. The isolator can be adjusted according to the needs of use-80pa~80pa, the normal product maintains 40pa~60pa during aseptic operation, the pressure is maintained to the set value ±5pa under static conditions, and the two modes of positive pressure and negative pressure can be preset and stored , Adjust according to demand;

7. The system design meets the requirements of GMP, 2015 Pharmacopoeia, USP/EP, and the control system can meet the 21CFR part11 electronic signature and electronic record requirements;

- The air source is clean filtered compressed air or nitrogen, and the air source pressure is 0.4MPa~0.6MPa.

Specification

| Name | VHP Aseptic Isolator |

| Power | 380±38V, 50±5Hz, 25A |

| Maximum power | ≤4000W |

| Built-in bacteria collector | 1-2 |

| Airflow method | Unidirectional flow |

| Display | 12.1 inch tablet |

| Noise | <65dB(A) |

| Application | Aseptic filling, sampling |

| Internal environment | Class A |

| System | PLC |

| Cusom | Provided |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products