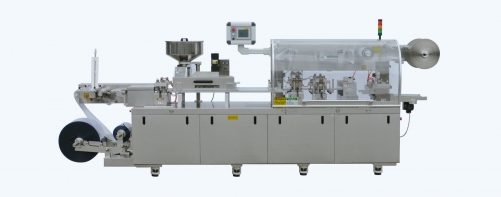

Blister Packing Machine

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

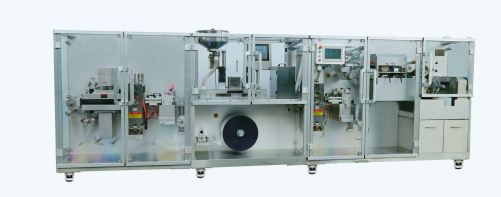

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.

Thanks to rotary sealing style (alu-pvc) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).

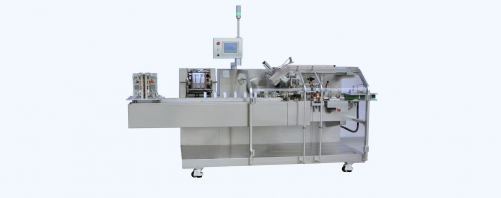

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Can be connected to subsequent machines, e.g., High-Speed Cartoners, Stretch-Banding Machine, and Case Packer, etc. to form a whole pharmaceutical packaging line.

This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

The machine runs stable and provides easy changeover for different sizes of cartons.

It can fold leaflets, open cartons, insert the products and leaflets into cartons, emboss, tuck-in, or hot-melt closures and automatically discharge cartons.

Larger area of forming and sealing station, high speed of embossing and punching station, suitable for mass batch production.

The shrinkage of the packaging material is minimized to ensure the synchronization of the blister pocket by means of a double servo-regulated drag system.

The use of aluminum offers a nearly complete barrier for water, light, and oxygen, allowing an exte

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

1