Blister Machine DPH260

Brief introduction

Can be connected to subsequent machines, e.g., High-Speed Cartoners, Stretch-Banding Machine, and Case Packer, etc. to form a whole pharmaceutical packaging line.

Description

Customer Case

Featured Products

. The working area is in cantilever construction. Separation of drive and operating zones are in compliance with pharmaceutical requirements.

. Accommodates forming material reels of up to 600mm in diameter and a waste material trimming cutter, which allows production runs uninterrupted of approximately 90 minutes, therefore, reducing the material replacement frequency.

. Equipped with integrated forming material splicer to enhance efficiency during material replacement.

. The upper and lower plates adopt the contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

. Equipped with automatic format locking, the positioning system achieves extremely straightforward format changeover

. Window frame type no-waste-trimming cutter saves packaging materials.

. Adopts transverse cutter which easily collects its blister card and rejects faulty blister.

. All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

. Can be connected to subsequent machines, e.g., High-Speed Cartoners, Stretch-Banding Machine, and Case Packer, etc. to form a whole pharmaceutical packaging line.

Gallery

This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

The cold-forming station for ALU.

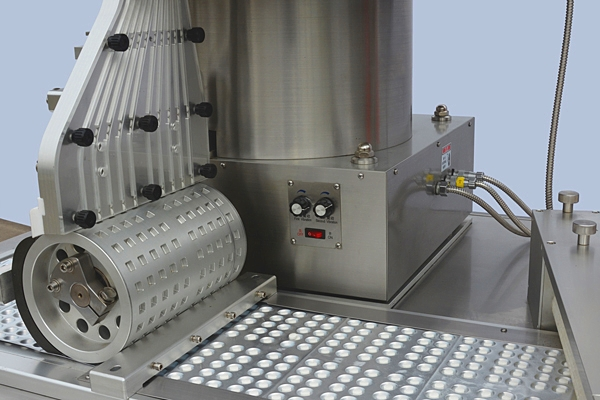

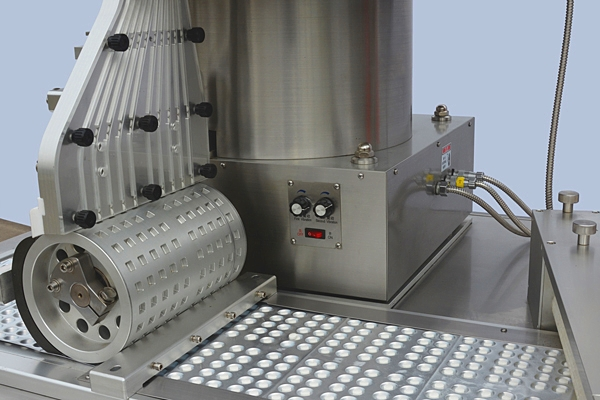

Track feeder for flat tablets; consists of a hopper, vibratory chute, tracks and rolling drum.

The rolling drum rotation is synchronized with web index of the machine, the product remains in a drum pocket until it is released into the blister pocket.

After feeding, the clearing brush removes extra capsules from the webbing to prevent them from entering the sealing station.

The rotary sealing station and embossing station.

Blister Packing Machine embossing station.

Adopts transverse cutter which easily collects its blister card

There are two waste tanks here for alternative use.

Pinhole detection system for quality assurance of blister packaging (optional).

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

. Accommodates forming material reels of up to 600mm in diameter and a waste material trimming cutter, which allows production runs uninterrupted of approximately 90 minutes, therefore, reducing the material replacement frequency.

. Equipped with integrated forming material splicer to enhance efficiency during material replacement.

. The upper and lower plates adopt the contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

. Equipped with automatic format locking, the positioning system achieves extremely straightforward format changeover

. Window frame type no-waste-trimming cutter saves packaging materials.

. Adopts transverse cutter which easily collects its blister card and rejects faulty blister.

. All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

. Can be connected to subsequent machines, e.g., High-Speed Cartoners, Stretch-Banding Machine, and Case Packer, etc. to form a whole pharmaceutical packaging line.

Gallery

This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

The cold-forming station for ALU.

Track feeder for flat tablets; consists of a hopper, vibratory chute, tracks and rolling drum.

The rolling drum rotation is synchronized with web index of the machine, the product remains in a drum pocket until it is released into the blister pocket.

After feeding, the clearing brush removes extra capsules from the webbing to prevent them from entering the sealing station.

The rotary sealing station and embossing station.

Blister Packing Machine embossing station.

Adopts transverse cutter which easily collects its blister card

There are two waste tanks here for alternative use.

Pinhole detection system for quality assurance of blister packaging (optional).

Main Technical Parameters

| Max. Speed: | alu/alu 100 punches/min. alu/pvc 200 punches/min. |

| Max. Forming Area: | 250×250mm |

| Max Forming Depth: | 12mm |

| Material: | Max. width 265mm |

| Machine Power: | 16.7kw |

| Machine Dimension: | 4600mm×1250mm×2000mm |

| Machine Weight: | 3200kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.