Blister Machine DPP80

Brief introduction

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.

Description

Customer Case

Featured Products

The characteristics of Blister Machine DPP80:

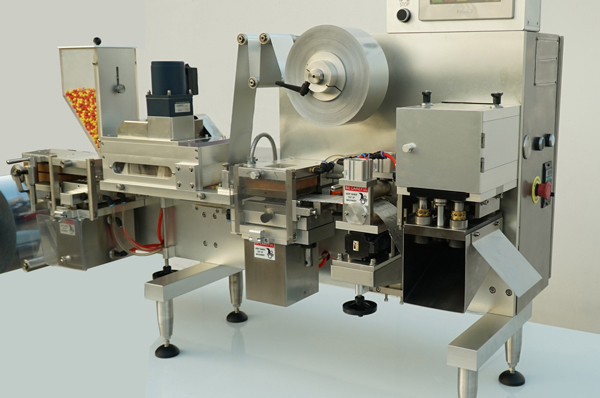

DPP80 is a compact, customizable, commercially competitive blister packaging machine for clinical trial laboratories and facilities requiring low-volume packaging solutions.

Produces small batches of all types of blister packs including thermoformed and cold-formed.

Easy user interface.

Compact space-saving, tabletop design for convenient blister packaging.

Fast set-up and the minimal training required.

Tool-less changeover for format parts.

Benefits:

Bring your blister packing in-house instead of booking time on production lines or outsourcing to a third party – minimizes delays, allowing your new drug product to get to market sooner.

Fast & easy set-up – no specialist knowledge is required to operate so there is no need for an engineer to be present

Compact, portable design.

Jornen can design your new blister packs. This is especially useful for customers who conduct clinical trials. We can advise them on how to rationalize the number of different tools needed, even if the lab needs to package many different products

Fully cGMP, so it is quick to clean – requires 5 minutes

Fast changeover – reduces down-time between production batches.

Application:

Blister Machine DPP80 is ideal for producing small batches of high-quality blister packs in:

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.

Gallery

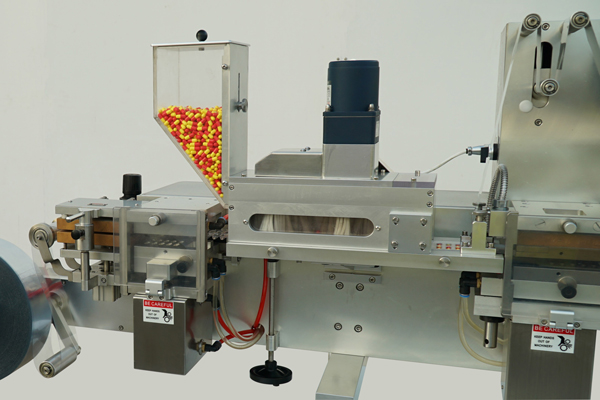

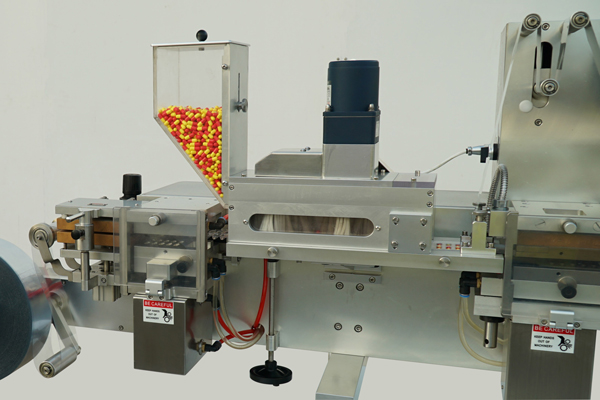

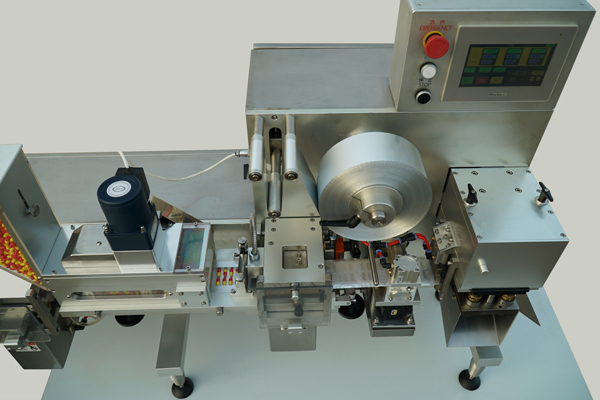

The forming material is unwound from the reel and guided through the guide rollers to forming station.

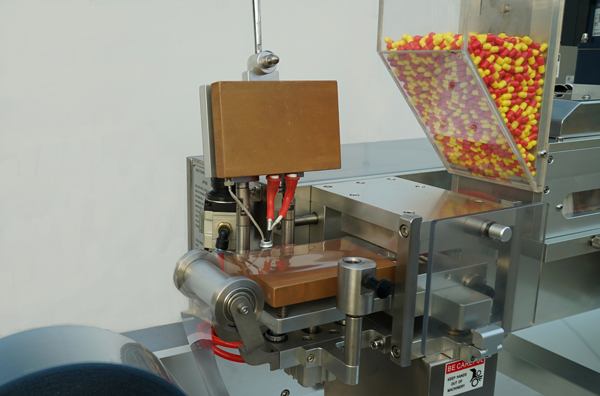

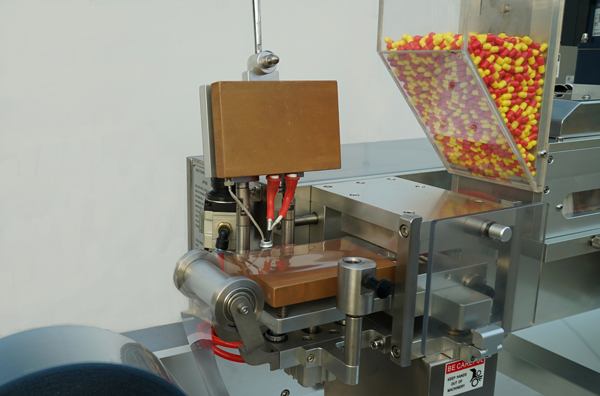

The Forming Station for all types of blister packs including thermoformed and cold-formed.

Can equipped the Universal Feeder, but due to the short feeding area the feeding can not achieve high rate.

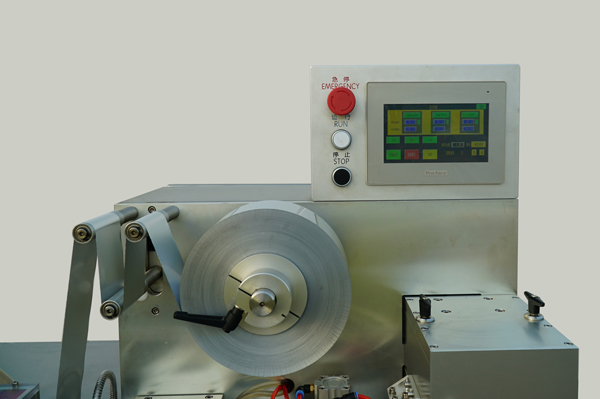

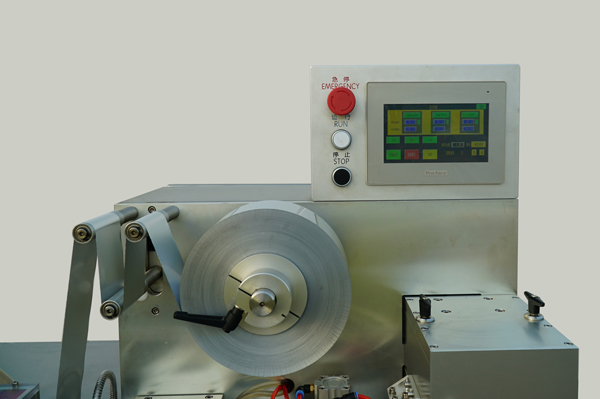

The high luminosity liquid crystal color touch screen with wide angle inspection.

The lidding material is unwound from the reel and guided through the guide rollers to sealing station.

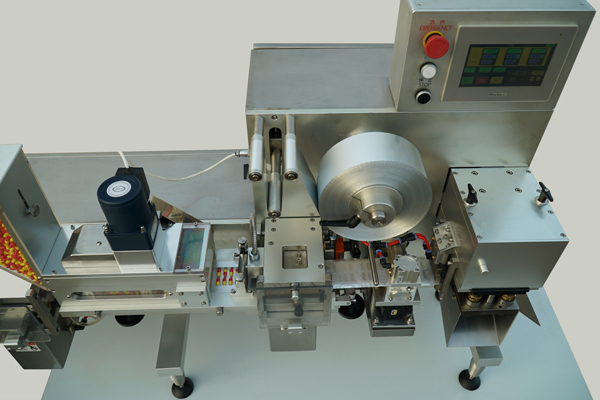

The forming and sealing station equipped safety covers for safe operation.

The material drag system adopts a precise servo motor to achieve stable, accurate running and allows blister length to be set freely.

The Cutting Station discharge the blister cards and waste material in different direction.

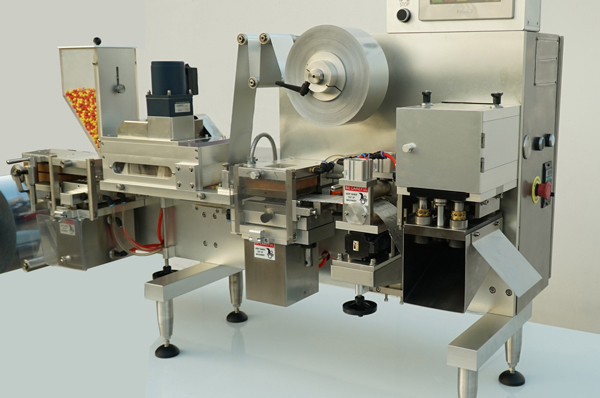

All the main parts are made of premium stainless steel and alu-alloy material, and machined by advanced high precision CNC tooling machines.

Cantilever construction, separation of driving and operating zones, so it is quick to clean. Fully pharmaceutical cGMP requirement.

The contact forming heating station can be opened up for very conveniently cleaning.

Extremely straightforward format changeover.

Tool-free changeover of format parts, reduces down-time between production batches.

Fast & easy set-up – no specialist knowledge is required to operate so there is no need for an engineer to be present.

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

DPP80 is a compact, customizable, commercially competitive blister packaging machine for clinical trial laboratories and facilities requiring low-volume packaging solutions.

Produces small batches of all types of blister packs including thermoformed and cold-formed.

Easy user interface.

Compact space-saving, tabletop design for convenient blister packaging.

Fast set-up and the minimal training required.

Tool-less changeover for format parts.

Benefits:

Bring your blister packing in-house instead of booking time on production lines or outsourcing to a third party – minimizes delays, allowing your new drug product to get to market sooner.

Fast & easy set-up – no specialist knowledge is required to operate so there is no need for an engineer to be present

Compact, portable design.

Jornen can design your new blister packs. This is especially useful for customers who conduct clinical trials. We can advise them on how to rationalize the number of different tools needed, even if the lab needs to package many different products

Fully cGMP, so it is quick to clean – requires 5 minutes

Fast changeover – reduces down-time between production batches.

Application:

Blister Machine DPP80 is ideal for producing small batches of high-quality blister packs in:

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.

Gallery

The forming material is unwound from the reel and guided through the guide rollers to forming station.

The Forming Station for all types of blister packs including thermoformed and cold-formed.

Can equipped the Universal Feeder, but due to the short feeding area the feeding can not achieve high rate.

The high luminosity liquid crystal color touch screen with wide angle inspection.

The lidding material is unwound from the reel and guided through the guide rollers to sealing station.

The forming and sealing station equipped safety covers for safe operation.

The material drag system adopts a precise servo motor to achieve stable, accurate running and allows blister length to be set freely.

The Cutting Station discharge the blister cards and waste material in different direction.

All the main parts are made of premium stainless steel and alu-alloy material, and machined by advanced high precision CNC tooling machines.

Cantilever construction, separation of driving and operating zones, so it is quick to clean. Fully pharmaceutical cGMP requirement.

The contact forming heating station can be opened up for very conveniently cleaning.

Extremely straightforward format changeover.

Tool-free changeover of format parts, reduces down-time between production batches.

Fast & easy set-up – no specialist knowledge is required to operate so there is no need for an engineer to be present.

Main Technical Parameters

| Max. Speed: | 27 punches/min. |

| Max. Output: | 27 blisters/min. ( blister size 57×80mm) |

| Max. Forming Area: | 70×100mm |

| Max Forming Depth: | 12mm |

| Material:Max. width: | 80mm |

| Machine Power: | 2.5kw |

| Machine Dimension (LxWxH): | 1600×520×1050mm |

| Machine Weight: | 170kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.