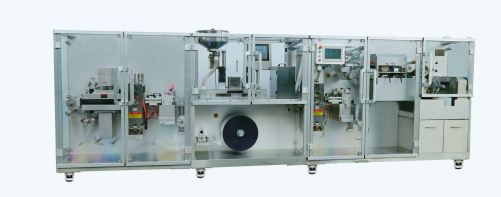

Blister Machine BMP270H

Brief introduction

Larger area of forming and sealing station, high speed of embossing and punching station, suitable for mass batch production.

Description

Customer Case

Featured Products

> The main structure has a vertical partition to separate the drive section (rear) from the operating zones (front).

> GMP-compliant cantilever (balcony type) layout for easy, pharmaceutically compliant cleaning.

> Adopts digital position indicator achieves straightforward adjustment.

> Equipped with format locking, positioning system, and quick-fitting, tool-free design, achieves extremely straightforward format changeover.

> In the sealing station, when the machine stops, the heating sealing mold can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

> Sealing pressure adopts the gas-hydraulic pressure cylinder, so the pressure can be set freely according to the sealing area (commonly a larger sealing area requires higher pressure).

> This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

> The upper and lower plates adopt a contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

> Using a quick-fitting design enables the replacement of lidding material easily within 10 seconds.

> The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

> Larger area of forming and sealing station, high speed of embossing and punching station, suitable for mass batch production.

> Glass safety doors assure safe operation.

See our machines running in factory

Gallery

The machine accommodates forming material reels of up to 600mm in diameter.

The machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

Adopt contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

Equipped with format locking, positioning system and quick-fitting, tool-free design, achieves extremely straightforward format changeover.

Larger area of forming and sealing station, suitable for mass batch production.

The tuber feeder can fill the entire index at once while the webbing is stationary (optional).

Integrated product inspection system with color camera can reject faulty blisters automatically (optional).

The high luminosity liquid crystal color touch screen.

The blister cards are punched, collected by the vacuum arm, the faulty blister cards can be rejected automatically (optional).

Pinhole detection system for quality assurance of blister packaging (optional).

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

> GMP-compliant cantilever (balcony type) layout for easy, pharmaceutically compliant cleaning.

> Adopts digital position indicator achieves straightforward adjustment.

> Equipped with format locking, positioning system, and quick-fitting, tool-free design, achieves extremely straightforward format changeover.

> In the sealing station, when the machine stops, the heating sealing mold can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

> Sealing pressure adopts the gas-hydraulic pressure cylinder, so the pressure can be set freely according to the sealing area (commonly a larger sealing area requires higher pressure).

> This machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

> The upper and lower plates adopt a contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

> Using a quick-fitting design enables the replacement of lidding material easily within 10 seconds.

> The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

> Larger area of forming and sealing station, high speed of embossing and punching station, suitable for mass batch production.

> Glass safety doors assure safe operation.

See our machines running in factory

Gallery

The machine accommodates forming material reels of up to 600mm in diameter.

The machine is equipped with an integrated forming material splicer to enhance efficiency during material replacement.

Adopt contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

Equipped with format locking, positioning system and quick-fitting, tool-free design, achieves extremely straightforward format changeover.

Larger area of forming and sealing station, suitable for mass batch production.

The tuber feeder can fill the entire index at once while the webbing is stationary (optional).

Integrated product inspection system with color camera can reject faulty blisters automatically (optional).

The high luminosity liquid crystal color touch screen.

The blister cards are punched, collected by the vacuum arm, the faulty blister cards can be rejected automatically (optional).

Pinhole detection system for quality assurance of blister packaging (optional).

Main Technical Parameters

| Max. Speed: | alu/pvc 150 punches/min. |

| Max. Output: | 400 blisters/min. (alu/pvc blister size 57× 80mm) |

| Max. Forming Area: | 260×210mm |

| Max Forming Depth: | 17mm |

| Material: | Max. width 270mm |

| Machine Power: | 19kw |

| Machine Dimension: | 5500×1500×2000mm (5 stations) |

| Machine Weight: | 3200kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.