Antibiotic washing sterilization filling production liner

Brief introduction

The full automatic production linkage line of antibiotic bottle washing, drying, filling and filling is completely according to the GMP standard, which is designed for the high quality and high yield of the bottle. The linkage line consists of vertical ul

Description

Customer Case

Featured Products

Brief introduction:

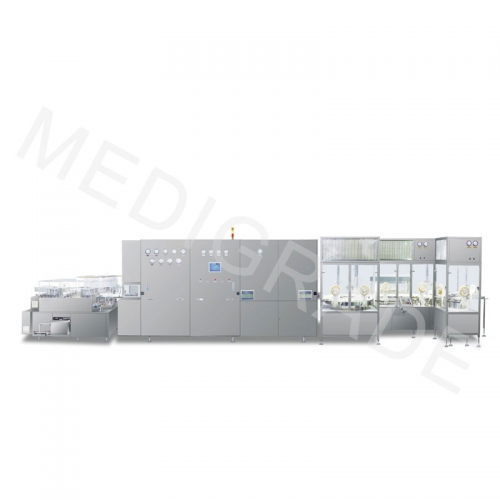

The full automatic production linkage line of antibiotic bottle washing, drying, filling and filling is completely according to the GMP standard, which is designed for the high quality and high yield of the bottle. The linkage line consists of vertical ultrasonic washing machine, hot air circulating tunnel sterilization oven and filling machine. The vertical ultrasonic washing machine can complete the ultrasonic roughing of the bottle, cleaning the outer wall of the bottle, and cleaning the three air and three water in the bottle. The sterilization oven of hot air circulation tunnel can be used to dry and sterilize the cleaning bottles. Filling machine can complete the filling and filling function. This linkage is equipped with advanced instruments and instruments at home and abroad. It can detect, print and store process parameters online. Meanwhile, it is equipped with an isolation protection system on the filling machine, which conforms to the new GMP requirements. This machine is a high intelligent machine for the mechatronics, the product performance is stable, the operation is simple and reliable, the appearance is beautiful. The machine can meet the production requirements of different bottle specifications and production yield according to the user process requirements. Can be used alone.

Technical parameters:

If you are interested in this machine, please contact me: Nana Zhang

Shanghai Medigrade Industry Co.,Ltd

Waigaoqiao Free Trade Zone, Shanghai,China. 200137

Cell Phone: 0086-15800947006

Tel: 0086-21-58589972

Fax: 0086-21-68689726

https://medigrade.en.made-in-china.com/ made-in-china.com

The full automatic production linkage line of antibiotic bottle washing, drying, filling and filling is completely according to the GMP standard, which is designed for the high quality and high yield of the bottle. The linkage line consists of vertical ultrasonic washing machine, hot air circulating tunnel sterilization oven and filling machine. The vertical ultrasonic washing machine can complete the ultrasonic roughing of the bottle, cleaning the outer wall of the bottle, and cleaning the three air and three water in the bottle. The sterilization oven of hot air circulation tunnel can be used to dry and sterilize the cleaning bottles. Filling machine can complete the filling and filling function. This linkage is equipped with advanced instruments and instruments at home and abroad. It can detect, print and store process parameters online. Meanwhile, it is equipped with an isolation protection system on the filling machine, which conforms to the new GMP requirements. This machine is a high intelligent machine for the mechatronics, the product performance is stable, the operation is simple and reliable, the appearance is beautiful. The machine can meet the production requirements of different bottle specifications and production yield according to the user process requirements. Can be used alone.

Technical parameters:

| Application | 2-20ml | 2-100ml | 2-100ml | 2-100ml | |

| Capacity | 100 bottles/min | 250-50bottles/min | 350-50 bottles/min | 500-50 bottles/min | |

| Associated equipment |

QCLX20 SZAX450/220 DGSX6 | QCLX60 SZAX620/3400 DGSX8 | QCLX80 SZAX620/5000 DGSX12 |

QCLX100 SZAX820/6500 DGSX16 |

|

| Damage rate | ≤0.01% | ||||

| Filling accuracy |

Servo control | ≤±1.0% |

|||

| Peristaltic pump | ≤±2.0% | ||||

| Water for injection |

Pressure | 0.3-0.5MPa | |||

| Consumption | 0.35m³/h | 0.4m³/h | 0.6m³/h | 0.8m³/h | |

| Air consumption |

Pressure | ||||

| Consumption | 24m³/h | 28m³/h | 45m³/h | 50m³/h | |

| Fresh air replenishm | Air cooled | 1500m³/h | 2000m³/h | 3000m³/h | 4100m³/h |

| Water cooling | 200m³/h | 400m³/h | 500m³/h | 700m³/h | |

| Vacuum | Pressure | 600pa | |||

| Consumption | 20m³/h | 40m³/h | 50m³/h | 80m³/h | |

| Power supply | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz | |

| Motor Power(kw) | 36kw | 62kw | 97kw | 106kw | |

| Noise | 68db | 70db | 72db | 74db | |

| Weight | 4200kg | 7100kg | 8700kg | 10800kg | |

| Dimension | 5540 x 1645 x 1965mm | 9926 x 1880 x 2200mm | 11483 x 2352 x 2070mm | 12983 x 2585 x 2245mm | |

If you are interested in this machine, please contact me: Nana Zhang

Shanghai Medigrade Industry Co.,Ltd

Waigaoqiao Free Trade Zone, Shanghai,China. 200137

Cell Phone: 0086-15800947006

Tel: 0086-21-58589972

Fax: 0086-21-68689726

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

This machine is a new generation of the ampoule filling and sealing machine for 1-20ml D type ampoule. It adopts the rectangular way to transfer ampoules, in such case, the transferring is steady, lower braking rate. A new type of clutch is mounted under

This series used to sterilize Chinese traditional medicine, corniness, tea, spice and other things like powder. During the whole working process, the jacket is first used to pre-heat the device, saturated steam is applied as sterilization medium for steri