Oral liquid linkage production line

Brief introduction

This equipment is suitable for liquid glass bottles for medicine packaging materials of liquid production, the bottle to take off the bag into the bottle washing machine can automatically complete the ultrasonic washing, after "three -water plus 3-air" cl

Description

Customer Case

Featured Products

Brief introduction:

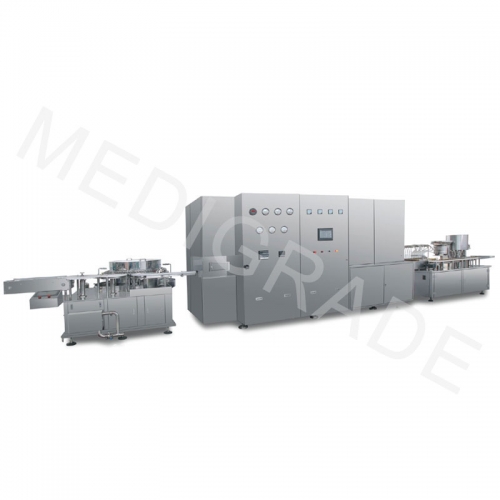

This equipment is suitable for liquid glass bottles for medicine packaging materials of liquid production, the bottle to take off the bag into the bottle washing machine can automatically complete the ultrasonic washing, after "three -water plus 3-air" cleaning and disinfection of tunnel oven drying, tracking, automatic filling, hang, cover, high speed rolling process, such as linkage line from HHXQL type vertical ultrasonic bottle washer, HHX - RS heat radiation of tunnel type oven (or HHX - RF tunnel type hot air circulation drying oven), HHGL10 oral liquid filling and other components of the rolling machine, the entire process by PLC to realize automation.(Note: right diagram is tunnel thermal radiation drying oven).

Features:

1. The washing bottle adopts the mechanical hand bottle to track the insert type "3 water +3 gas" alternately flushing to ensure the effect of the bottle washing.

2. The heat radiation or hot air circulation is used to sterilize and sterilize the high temperature. The heat distribution is uniform, to ensure the sterilization and drying effect.

3. The metering pump or peristaltic pump can be set up according to demand, with tracking and filling, with high loading precision, no leakage, no bubble and no splash when filling the general liquid. The rolling cover adopts the traditional 3 knife type rolling cover to ensure the sealing effect of the bottle mouth.

4. The whole line adopts advanced control system technology, can be controlled by single machine and whole line interlocking, with stable performance.

5. The oral liquid filling machine is simple in operation, high production efficiency but low bottle breaking rate.

Technical parameters:

If you are interested in this machine, please contact me: Nana Zhang

Shanghai Medigrade Industry Co.,Ltd

Waigaoqiao Free Trade Zone, Shanghai,China. 200137

Cell Phone: 0086-15800947006

Tel: 0086-21-58589972

Fax: 0086-21-68689726

https://medigrade.en.made-in-china.com/ made-in-china.com

This equipment is suitable for liquid glass bottles for medicine packaging materials of liquid production, the bottle to take off the bag into the bottle washing machine can automatically complete the ultrasonic washing, after "three -water plus 3-air" cleaning and disinfection of tunnel oven drying, tracking, automatic filling, hang, cover, high speed rolling process, such as linkage line from HHXQL type vertical ultrasonic bottle washer, HHX - RS heat radiation of tunnel type oven (or HHX - RF tunnel type hot air circulation drying oven), HHGL10 oral liquid filling and other components of the rolling machine, the entire process by PLC to realize automation.(Note: right diagram is tunnel thermal radiation drying oven).

Features:

1. The washing bottle adopts the mechanical hand bottle to track the insert type "3 water +3 gas" alternately flushing to ensure the effect of the bottle washing.

2. The heat radiation or hot air circulation is used to sterilize and sterilize the high temperature. The heat distribution is uniform, to ensure the sterilization and drying effect.

3. The metering pump or peristaltic pump can be set up according to demand, with tracking and filling, with high loading precision, no leakage, no bubble and no splash when filling the general liquid. The rolling cover adopts the traditional 3 knife type rolling cover to ensure the sealing effect of the bottle mouth.

4. The whole line adopts advanced control system technology, can be controlled by single machine and whole line interlocking, with stable performance.

5. The oral liquid filling machine is simple in operation, high production efficiency but low bottle breaking rate.

Technical parameters:

| Appliacbility range | 20-30ml(Oral liquid glass bottle) |

| Production capacity | 400 bottles/minute |

| Damage rate of bottle cleaning | ≤0.1% |

| Filling accuracy | ≤±1.0% |

| Qualified rate of cap screwing(capping) | 99.0% |

| Electric source | 380V/220V 50Hz |

| Total power | 68kw |

| Total length of linkage production line | 8.7m |

If you are interested in this machine, please contact me: Nana Zhang

Shanghai Medigrade Industry Co.,Ltd

Waigaoqiao Free Trade Zone, Shanghai,China. 200137

Cell Phone: 0086-15800947006

Tel: 0086-21-58589972

Fax: 0086-21-68689726

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

This machine is a new generation of the ampoule filling and sealing machine for 1-20ml D type ampoule. It adopts the rectangular way to transfer ampoules, in such case, the transferring is steady, lower braking rate. A new type of clutch is mounted under

This series used to sterilize Chinese traditional medicine, corniness, tea, spice and other things like powder. During the whole working process, the jacket is first used to pre-heat the device, saturated steam is applied as sterilization medium for steri