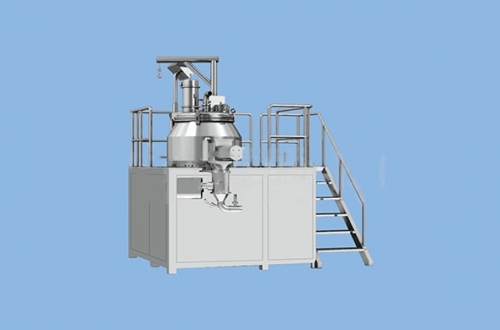

High shear wet type mixing granulator

Brief introduction

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It has been widely used in such industries as medicine, food, chemical industry, etc.

Description

Customer Case

Featured Products

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It has been widely used in such industries as medicine, food, chemical industry, etc.

- Features:easy cleaning,PLC control

- Production capacity:20-400(kg/batch)

- Suitable applications:Pharmaceutical, food, chemical

Product highlights

Detailed introduction

Working principleThe materials are fed into the mixing vessel through the vacuum feeder or lifting feeder. Through rotation and push by the mixing paddle at the bottom, they first move under a fluidizing status and get sufficient mixing. Then the adhesive is injected through the pressure spray gun to turn the dry powders into wet and soft materials. Meanwhile, they are made into even wet granules under the double actions of the mixing paddle and the high-speed cutter on the side wall. After granulation, the materials are discharged to the next procedure (milling or drying).

Features

▲The whole machine is made of high quality stainless steel.

▲It is provided with special mixing barrel and conical column of a compound structure. The corners on the inner wall are subjected to smooth transition and mirror polishing with easy cleaning and without material sticking.

▲The mixing and granulating procedure can be completed in one step with the materials in the closed mixing barrel.

▲It adopts PLC control. The mixing and granulating motors are subjected to variable frequency speed adjustment. All operations can be carried out automatically or manually.

▲It is provided with interlocking protection device to ensure safer operation.

▲It is equipped with printer to automatically print all process parameters, with the original records conforming to the actual ones.

▲It can be equipped with wet type milling machine and swing granulator and connect with fluid bed dryer to form a fully closed granulating production line.

Technical parameter

| Item Model | SHM- 100 | SHM- 150 | SHM- 200 | SHM- 300 | SHM- 400 | SHM- 500 | SHM-600 | SHM- 800 | SHM-1000 | |

| Production capacity (kg/batch) | 20~40 | 30-60 | 40-80 | 60-120 | 80-160 | 100-200 | 120-240 | 160-320 | 200-400 | |

| Mixing impeller motor power(kw) | 11 | 15 | 22 | 30 | 30 | 37 | 45 | 55 | 55 | |

| Mixing impeller rotation speed(rpm) | 0-200 | 0-200 | 0~200 | 0~200 | 0~200 | 0~170 | 0~170 | 0~150 | 0~120 | |

| Granulating agitator motor power(kw) | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | |

| Granulating agitator rotation speed(rpm) | 0-2900 | 0-2900 | 0-2900 | 0-2900 | 0-2900 | 0-2900 | 0-2900 | 0-2900 | 0-2900 | |

| Mill Power(kw) | 2.2 | 2.2 | 3 | 4 | 4 | 5.5 | 5.5 | 5.5 | 5.5 | |

| Mill Speed( rpm) | 0~900 | 0~900 | 0~900 | 0~900 | 0~900 | 0~900 | 0~900 | 0~900 | 0~900 | |

| Compressed air consumption(m³/min) | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 1 | 1 | 1 | 1 | |

| Compressed air pressure(MPa) | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | 03.-0.6 | |

| Equipment weight(kg) | 1200 | 1500 | 1800 | 2000 | 2200 | 2500 | 3000 | 3500 | 4000 | |

| Outline | L | 2200 | 2365 | 2580 | 2580 | 2605 | 2780 | 2780 | 2980 | 3180 |

| dimensions | L1 | 1800 | 1800 | 2000 | 2000 | 2000 | 2200 | 2280 | 2480 | 2680 |

| W | 2300 | 2400 | 2400 | 2600 | 2600 | 2800 | 2800 | 2900 | 3100 | |

| W1 | 1500 | 1600 | 1600 | 1800 | 1800 | 2000 | 2000 | 2100 | 2300 | |

| H | 2600 | 2600 | 3050 | 3050 | 3050 | 3050 | 3050 | 3250 | 3350 | |

| H1 | 1400 | 1400 | 1400 | 1400 | 1400 | |||||

Customer Case

Featured Products

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for resea

The machine is mainly used for online cleaning of equipment in the production process of solid preparations,used together with equipment such as fluid bed machine,coating machine and wet mixing granulator,It is also sulitable for the cleaning of industria