Hot melt extruder granulator

Brief introduction

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for resea

Description

Customer Case

Featured Products

Product Description

HME series laboratory extrusion line included a Lab Precise twin Screw Extruder, a Molding System, a Film Casting, Haul-off & Winding Machine and a SIEMENS PLC Touching Screen Control System.

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for research institute to develop new material formula and film shaping technology.

Main Features

1) Adopting international brand variable speed control motor to precisely control the screw rotating speed;

2) The 3D processed geometry screw elements maintain uniform gaps and achieve very good self-clean and precise plasticizing effect;

3) Using parallel two-axis high speed high torque gearbox to make the extruder applicable for more than 95% materials' compounding and extrusion technologies;

4) Emergency stop button protect safety to operate;

5) Optional side feeder for special materials, e.g. glass fiber;

6) Optional forced feeder to increase stability of feeding;

7) Optional liquid feeding equipment;

8) Optional gravimetric feeder

9) With CE certificate.

Product Application

1) Mixing, kneading and pelletizing of general plastics, engineering plastics, elastomer, etc.

2) Material plasticization, conveying and reactive extrusion;

3) High effective compounding of polymer alloy;

4) Modification of filled polymer;

5) Material exhaust vapor, violate and de-gas.

6) Specially suitable for the pharma testing processing.

Detailed Images

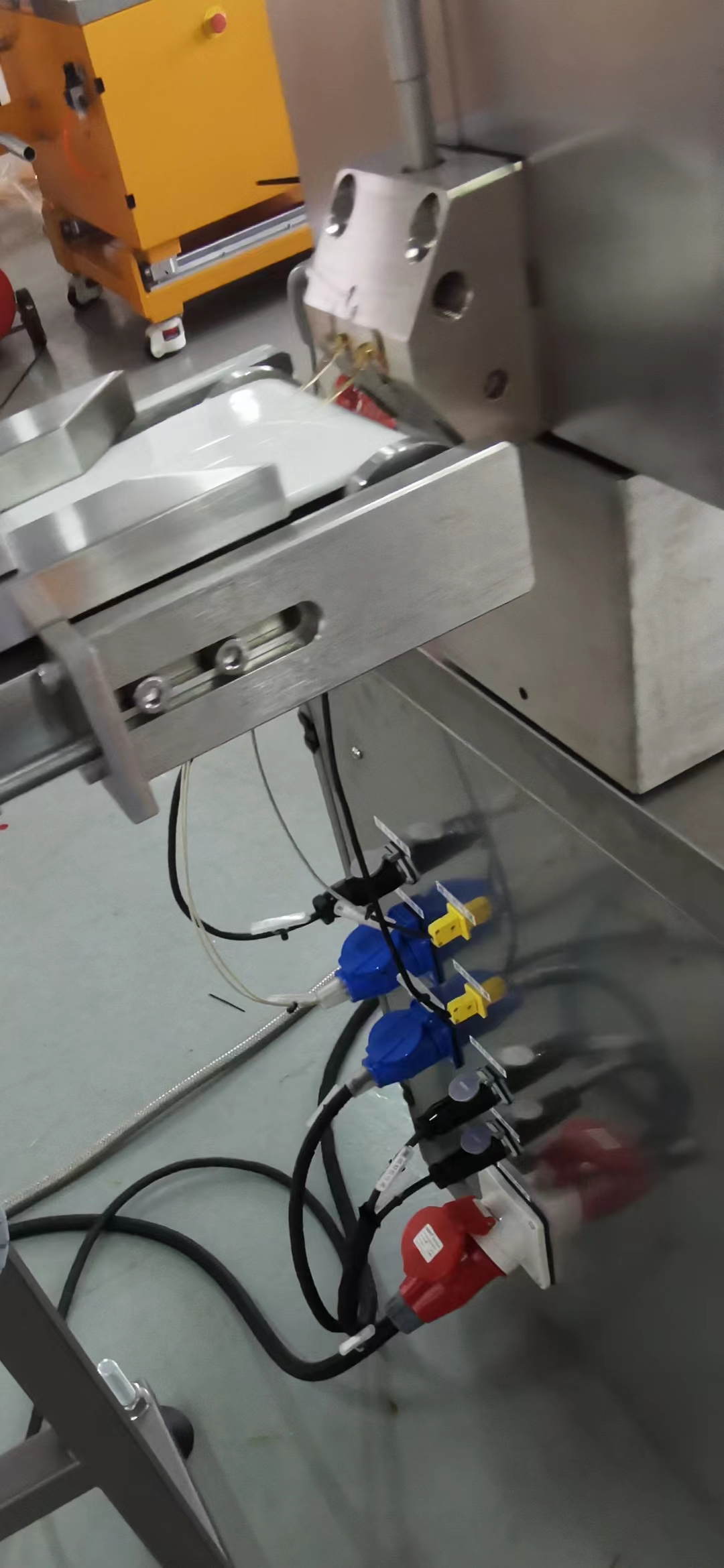

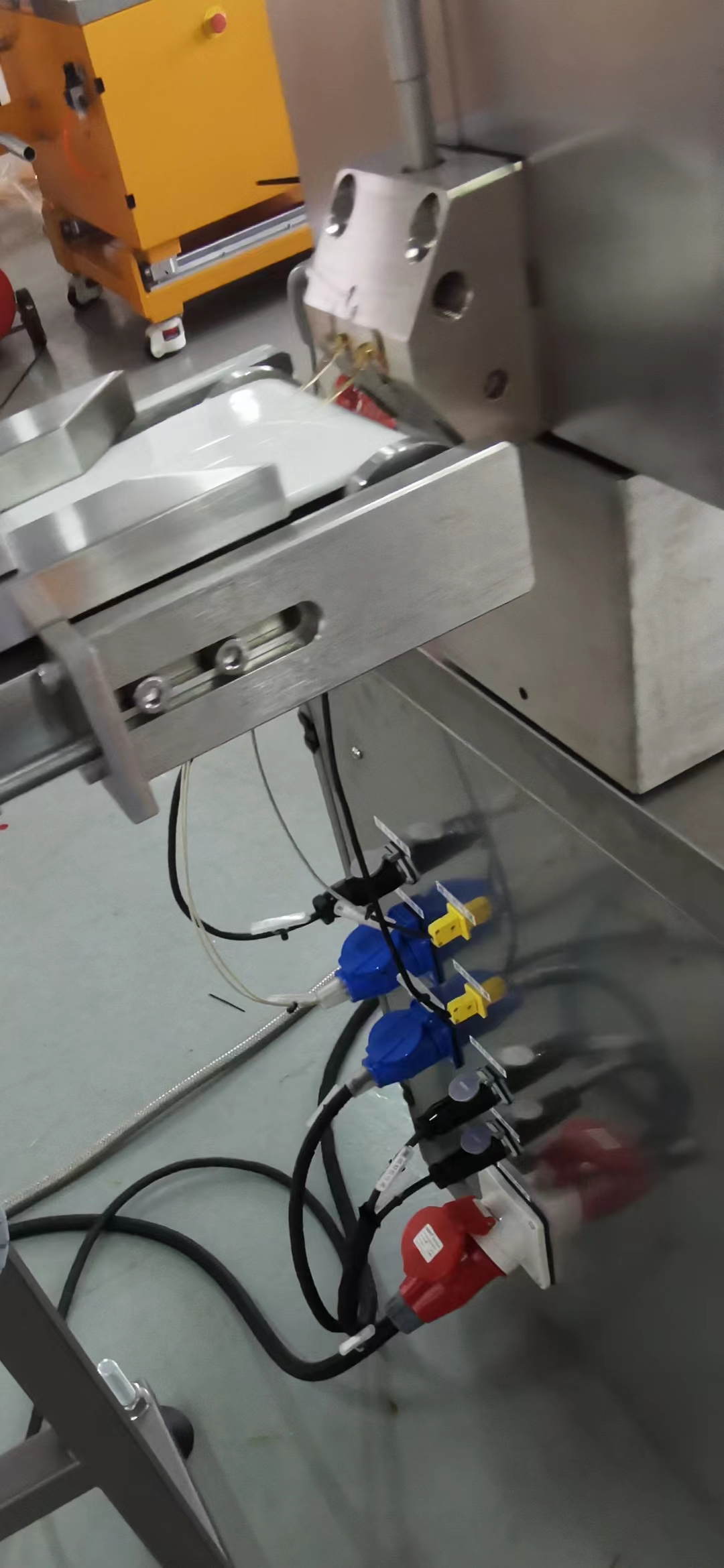

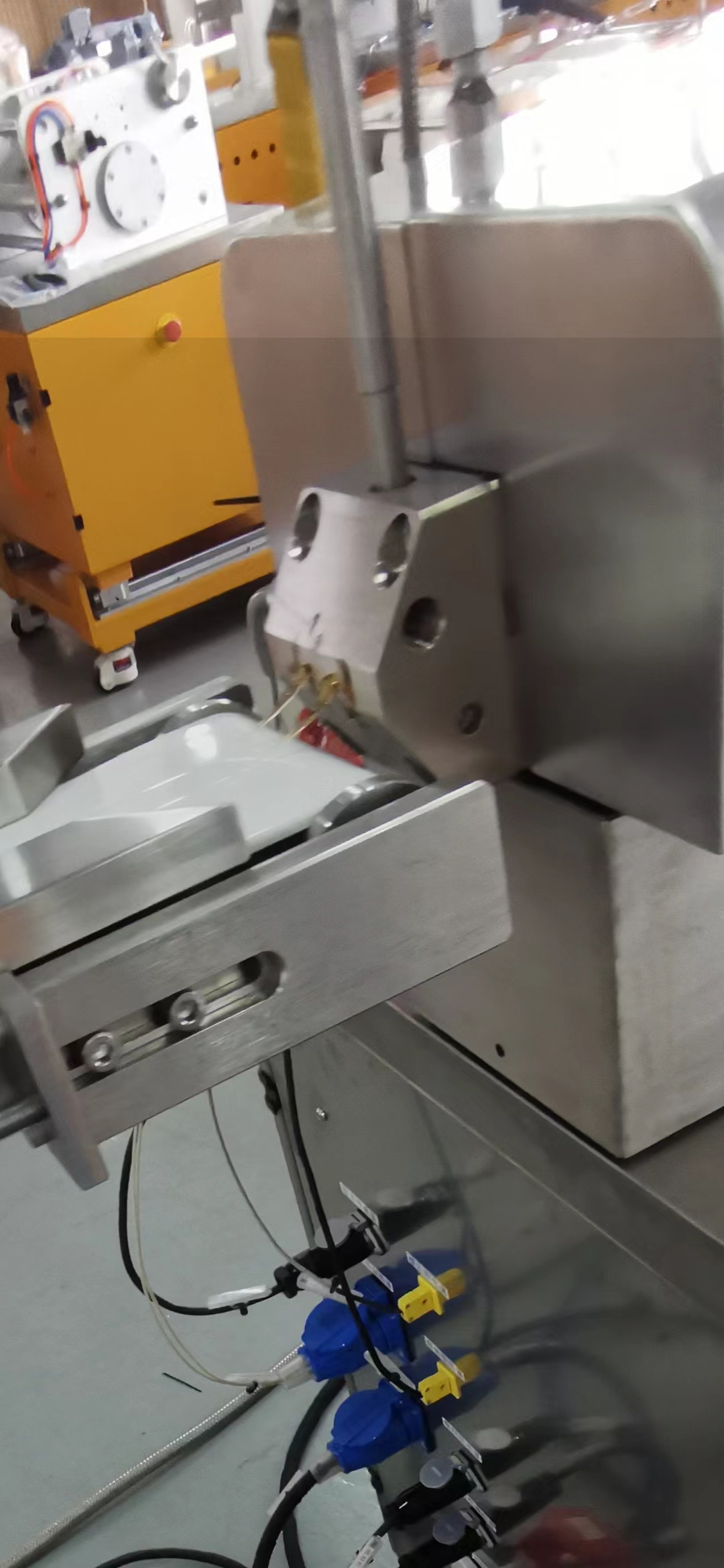

Machine Parts

Name: Main Feeder

Brand: Medigrade

Original: China

The machine was equipped with a standard stainless steel feeder. there is optional gravimetric main feeder or side feeder for special requirements.

Main Features

Name: Vacuum System

Brand: Medigrade

Original: China

The driving power of the vacuum system is 0.75KW. The maximum displacement is 64m2/h.

Machine Parts

Name: Die

Brand: Medigrade

Original: China

There is a strand die installed in the twin screw extruder.

Main Features

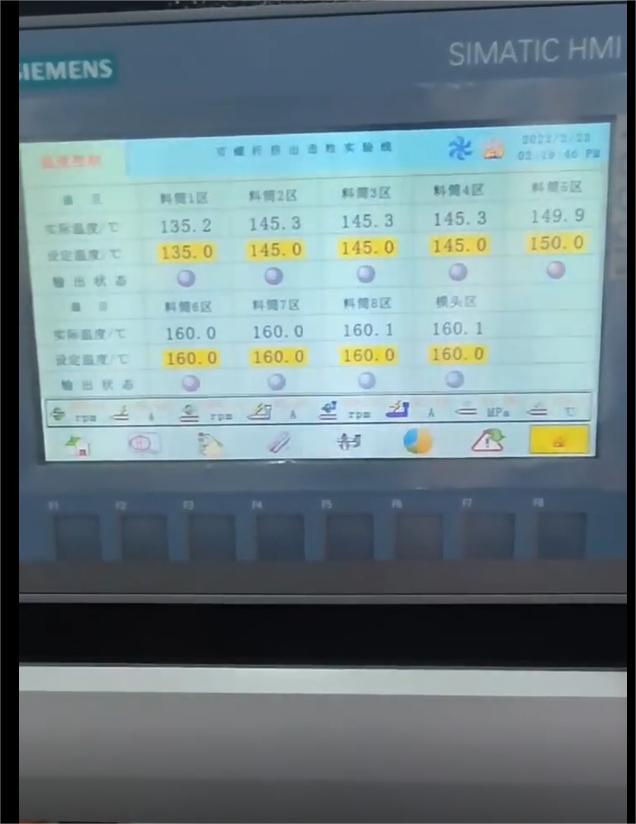

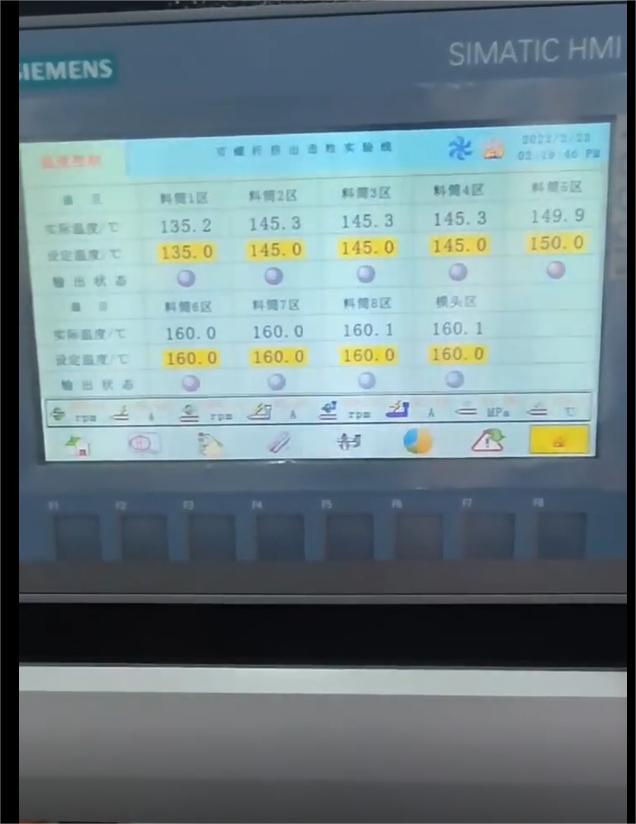

Name: PLC Tounching Screen Control System

Brand: Medigrade

Original: China

The equipment adopts SIEMENS PLC touching screen Control System. The important data such as melt temperature, melt pressure, torque are displaced instantly. and it is easy to be operated.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

| HME-20 Lab Twin screw hot melt extruder for pharma products & chemical & pharmaceutical machinery | |||

| Specification | Applicable materials | hot melt plastics | |

| Screw diameters | 21.7 | mm | |

| Max. screw rotating speed | 600 | rpm | |

| Screw L/D ratio | 40:1 | ||

| Motor power | 5.5 | KW | |

| Max. output | 20 | kg/h | |

| Torque | 71 | Nm | |

| Max. working temperature | 350 | ℃ | |

| Temperature control accuracy | +/- 1 | ℃ | |

| Working voltage | 380V/50Hz/3 phases or Customerized | ||

| Control method | SIEMENS TFT Touching Screen PLC control | ||

HME series laboratory extrusion line included a Lab Precise twin Screw Extruder, a Molding System, a Film Casting, Haul-off & Winding Machine and a SIEMENS PLC Touching Screen Control System.

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for research institute to develop new material formula and film shaping technology.

Main Features

1) Adopting international brand variable speed control motor to precisely control the screw rotating speed;

2) The 3D processed geometry screw elements maintain uniform gaps and achieve very good self-clean and precise plasticizing effect;

3) Using parallel two-axis high speed high torque gearbox to make the extruder applicable for more than 95% materials' compounding and extrusion technologies;

4) Emergency stop button protect safety to operate;

5) Optional side feeder for special materials, e.g. glass fiber;

6) Optional forced feeder to increase stability of feeding;

7) Optional liquid feeding equipment;

8) Optional gravimetric feeder

9) With CE certificate.

Product Application

1) Mixing, kneading and pelletizing of general plastics, engineering plastics, elastomer, etc.

2) Material plasticization, conveying and reactive extrusion;

3) High effective compounding of polymer alloy;

4) Modification of filled polymer;

5) Material exhaust vapor, violate and de-gas.

6) Specially suitable for the pharma testing processing.

Detailed Images

Machine Parts

Name: Main Feeder

Brand: Medigrade

Original: China

The machine was equipped with a standard stainless steel feeder. there is optional gravimetric main feeder or side feeder for special requirements.

Main Features

Name: Vacuum System

Brand: Medigrade

Original: China

The driving power of the vacuum system is 0.75KW. The maximum displacement is 64m2/h.

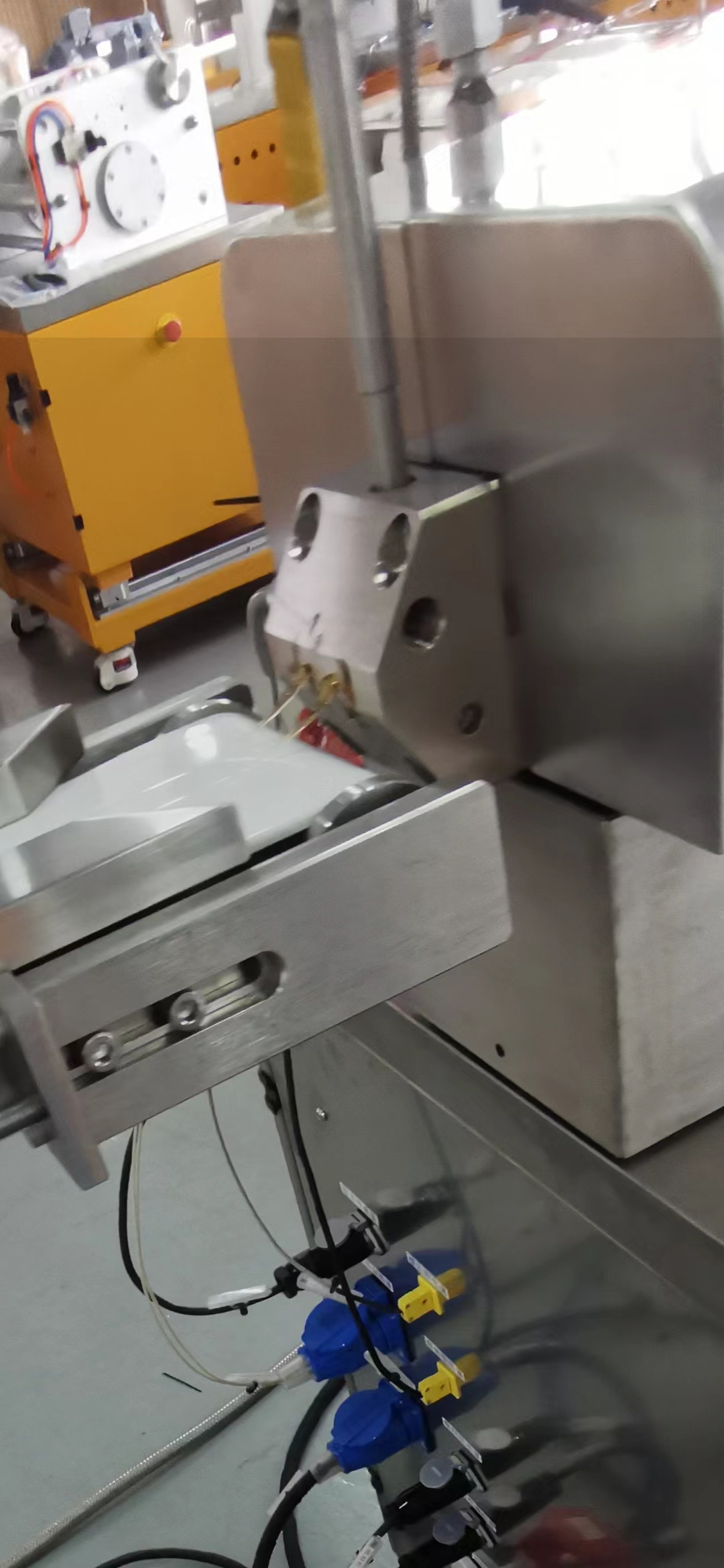

Machine Parts

Name: Die

Brand: Medigrade

Original: China

There is a strand die installed in the twin screw extruder.

Main Features

Name: PLC Tounching Screen Control System

Brand: Medigrade

Original: China

The equipment adopts SIEMENS PLC touching screen Control System. The important data such as melt temperature, melt pressure, torque are displaced instantly. and it is easy to be operated.

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for resea

The machine is mainly used for online cleaning of equipment in the production process of solid preparations,used together with equipment such as fluid bed machine,coating machine and wet mixing granulator,It is also sulitable for the cleaning of industria