Roller compactor MG series

Brief introduction

extrusion,crushing and granulating functions, directly makes powder into granules.It is especially suitable for granulation of materials which are wet,hot,easily broken down or agglomerated.It has been widely used in pharmaceutical,food. chemical and othe

Description

Customer Case

Featured Products

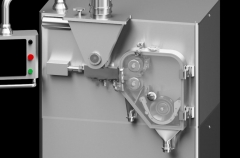

Extrusion,crushing and granulating functions, directly makes powder into granules.It is especially suitable for granulation of materials which are wet,hot,easily broken down or agglomerated.It has been widely used in pharmaceutical,food. chemical and other industries.In the pharmaceutical industry. granules made by the roller compactor can be directly pressed into tablets or filled into capsules.

- Features:compact structure,easy to clean and maintain

- Production capacity:5-200(kg/batch)

- Suitable applications:Pharmaceutical, food, chemical

Product highlights

Detailed introduction

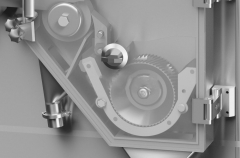

Working principleMixed with the ingredients of the dry powder material,by the vacuum feeder to the soli material,through the screw conveyor to the pressure chamber,the two high-pressure extrusion wheel to press the material into sheet with the required density and thickness,then through the miling system to make granules meet requirements to complete the granulation process.

Features

1.3 functions in one unit.These are compress.

2.Simplified process to obtain highly stable granules.No water or other liquid is added and no need drying,so the loss of active ingredients due to decomposition can be eliminated.

3.Pressure rollers with a water cooling system.

4.Overall modular design,compact structure,better space utilization.

5.The power area is separated from the work area to prevent cross contamination.

6.Horizontal feeding structure,exposed installation of extrusion system,easy to clean and maintain.

7.Meet GMP requirements.

Technical parameter

| Item Model | MG-5 | MG-15 | MG-50 | MG-100 | MG-200 |

| Feeding motor power(kw) | 0.37 | 0.55 | 0.75 | 2.2 | 4 |

| Extruding motor power(kw) | 0.55 | 0.75 | 1.5 | 3 | 5.5 |

| Granulating motor power(kw) | 0.37 | 0.37 | 0.55 | 1.1 | 1.5 |

| Oil pump motor power(kw) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Water cooler power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Production capacity(kg/h) | 5 | 15 | 50 | 100 | 200 |

| Weight(kg) | 500 | 700 | 900 | 1100 | 2000 |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

It not only has wide range of technology adjustment (including speed, temperature, pressure, thickness, etc.), but also has a lot of functions such as real-time parameter acquistion, graphic displaying, recording and storing. It is an ideal tool for resea

The machine is mainly used for online cleaning of equipment in the production process of solid preparations,used together with equipment such as fluid bed machine,coating machine and wet mixing granulator,It is also sulitable for the cleaning of industria