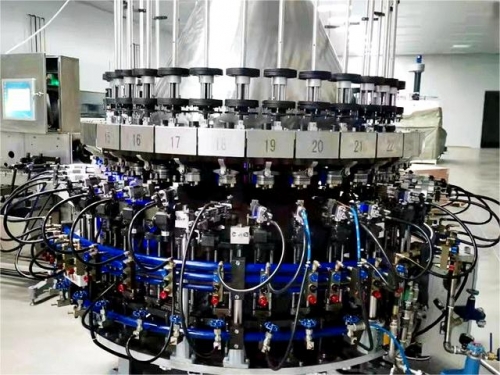

Vertical ampoule bottle making machine

Brief introduction

The machine is composed of four single machines: vertical ampoule bottle making machine, dotted scoring marking machine, pad outer tunnel and packaging machine. It can automatically complete ampoule bottle forming, dotted scoring, ring coloring, ampoule b

Description

Customer Case

Featured Products

AZ10 vertical ampoule bottle making machine

The whole line has high production capacity, high degree of automation, stable and reliable operation. The application results show that the performance indexes fully meet the requirements of customers and meet the requirements of similar foreign equipment.

The machine is composed of four single machines: vertical ampoule bottle making machine, dotted scoring marking machine, pad outer tunnel and packaging machine. It can automatically complete ampoule bottle forming, dotted scoring, ring coloring, ampoule bottle annealing and automatic packaging procedures, and can be applied to imported and domestic glass pipes at the same time.

The on-line detection system can realize the measurement of diameter, wire diameter, bubble diameter, neck diameter and neck size of bottle body in the production process.

Flame tracking deflector can accurately track glass tube and ampoule

Mark mechanism bottle and other devices, realize the same machine to complete the bottle length measurement and color ring marking drying and other processes, and can realize the synchronous linkage of each process with the main machine.

One easy fold ring mechanism two decorative ring mechanism.

Print a colored dot above the cut line to indicate its location.

Detachable screen printing device is composed of metal frame, patterned screen, etc.

The annealed detection device can realize the on-line detection of the internal stress, crack, dirt and other quality conditions of the bottle.

Automatic packaging can reduce workers use and cross contamination.

Main technical parameters

| Production speed: | 4000±10% pcs / hour |

| Applicable pipe diameter: | 8 mm - 22.5 mm |

| Applicable height: | 60mm-150mm |

| Applicable standards: | In line with YBB series and ISO series standards |

| Product qualified rate: | > 95% |

| Power of equipment: | 13kw,AC380V,50Hz |

| Overall size: | 14500mm*2200mm*2600mm |

| Weight of equipment: | 7000Kg |

| Value-added functions: | Automatic fire adjustment + visual detection |

Consumption

| Compressed air consumption: | 60~70 CBM/H |

| Oxygen consumption of | 1.8~9.5 CBM/H |

| Natural gas consumption | 0.6~3.5 CBM/H |

| Low pressure air consumption | 6~30 CBM/H |

| High pressure air consumption | 40~90 CBM/H |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case