Description

Customer Case

Featured Products

. High-speed, fully servo regulated, the culmination of our more than 30 years of professional experience.

. By integrating a rotary-style blistering and continuous motion cartoning module for packaging of pharmaceutical tablets and capsules, high efficiency and highly flexible, maximum output reaches 500carton/; it is ideal for mass production.

. Processes all common solid dose products and all types of forming material.

. The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and a waste material trimming cutter.

. Capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

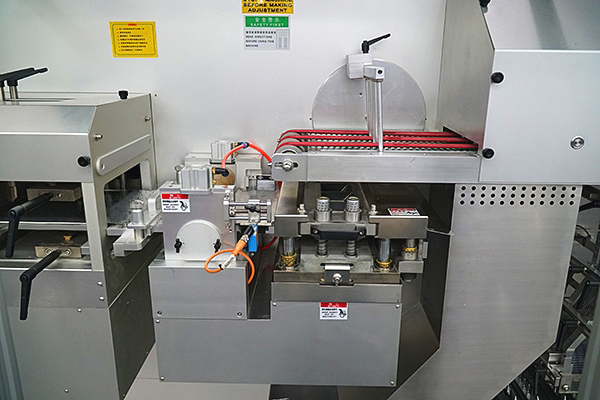

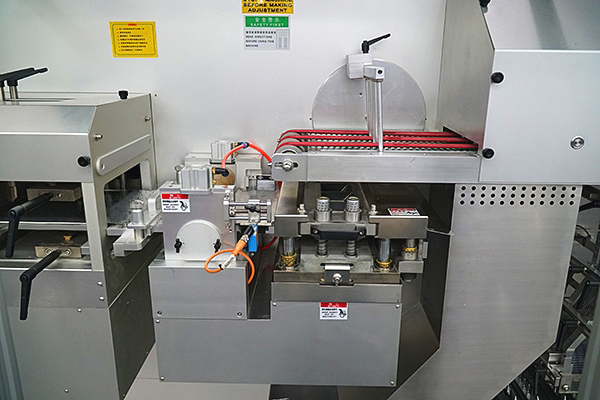

. The heart of a Blister Line is the connection between the Blister module and Cartoner module. In this line, the connection phase is truly innovative thanks to blister cards pick-up arms, vacuum conveyors, and the blister counting magazines that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

. GMP-compliant cantilever (balcony type) layout for easy pharmaceutically compliant cleaning.

. In the blister unit when the first reel’s film runs out in the blister module, it can automatically connect with the second without interruption to the machine (optional).

. The cartoning machine is truly ergonomic thanks to the innovative design whereby the product inserting device is placed at the rear; The conventional cartoning machine’s inserting device is placed at the front side, where it protrudes from the operation side and is less ergonomic.

. The cartoner module equipped a servo-regulated robot that can automatically load cartons when the carton magazine is low (optional).

. The blister and cartoner unit were optimally combined in this line, less than 12 meters in length, it provides easy changeover for different sizes of formats and cartons.

. This line adopts the fully-enclosed structure and safety door; it aligns with the stringent safety standards.

See our machines running in the pharmaceutical company.

Gallery

When the first reel’s PVC runs out, it can automatically connect with the second without interruption to the machine (optional).

Adopt the contact heating method that significantly reduces the forming temperature, the shrinkage of PVC, and power consumption are minimized.

Servo-regulated drag system achieves stable, accurate running. The blister length can be set freely through Touch Screen.

The tuber feeder can fill the entire index at once while the webbing is stationary.

Track feeder for capsules, flat and oblong tablets; consists of a hopper, vibratory chute, vibratory conveyor, and tracks.

The track-roller feeder for flat tablets; consists of a hopper, vibratory chute, tracks, and rolling drum.

After feeding, the clearing brush removes extra capsules from the webbing to prevent them from entering the sealing station.

Integrated product inspection system with a color camera can reject faulty blisters automatically (optional).

The servo-regulated magazines accurately control blister transfer and feeding to assure the stability of high running speed.

The Leaflet Folding Device makes the leaflet fold one to four-folds

The rotary carton feeder pick up cartons then places them in carton conveyor chain.

Innovative design to place the inserting device at the rear; The conventional front-placing design protrudes from the operation side is not ergonomic.

Adopts digital position indicator achieves straightforward adjustment.

At the end of the line, the cartons are discharged automatically.

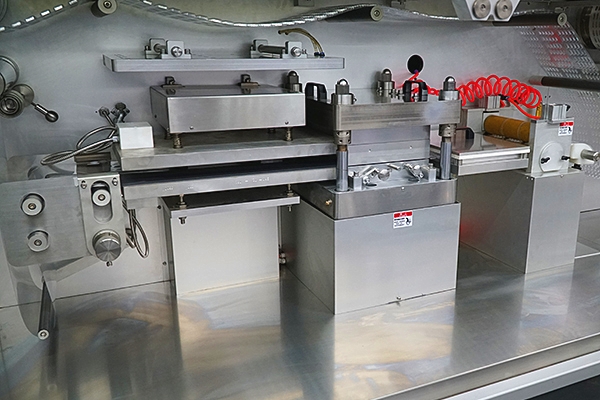

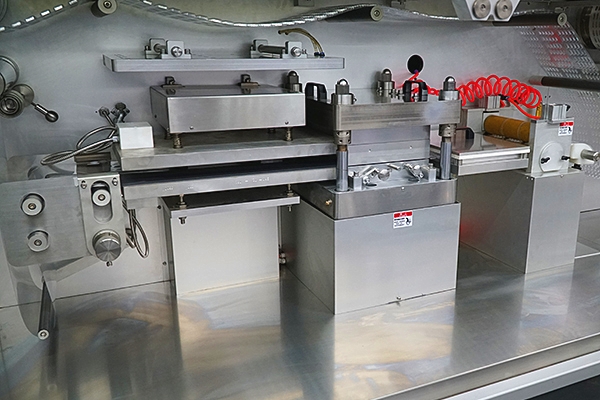

Tool-free changeover of forming mold.

Tool-free changeover of punching mold.

Adopts aluminum control enclosure and color Touch Screen User Interface.

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

. By integrating a rotary-style blistering and continuous motion cartoning module for packaging of pharmaceutical tablets and capsules, high efficiency and highly flexible, maximum output reaches 500carton/; it is ideal for mass production.

. Processes all common solid dose products and all types of forming material.

. The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and a waste material trimming cutter.

. Capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

. The heart of a Blister Line is the connection between the Blister module and Cartoner module. In this line, the connection phase is truly innovative thanks to blister cards pick-up arms, vacuum conveyors, and the blister counting magazines that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

. GMP-compliant cantilever (balcony type) layout for easy pharmaceutically compliant cleaning.

. In the blister unit when the first reel’s film runs out in the blister module, it can automatically connect with the second without interruption to the machine (optional).

. The cartoning machine is truly ergonomic thanks to the innovative design whereby the product inserting device is placed at the rear; The conventional cartoning machine’s inserting device is placed at the front side, where it protrudes from the operation side and is less ergonomic.

. The cartoner module equipped a servo-regulated robot that can automatically load cartons when the carton magazine is low (optional).

. The blister and cartoner unit were optimally combined in this line, less than 12 meters in length, it provides easy changeover for different sizes of formats and cartons.

. This line adopts the fully-enclosed structure and safety door; it aligns with the stringent safety standards.

See our machines running in the pharmaceutical company.

Gallery

When the first reel’s PVC runs out, it can automatically connect with the second without interruption to the machine (optional).

Adopt the contact heating method that significantly reduces the forming temperature, the shrinkage of PVC, and power consumption are minimized.

Servo-regulated drag system achieves stable, accurate running. The blister length can be set freely through Touch Screen.

The tuber feeder can fill the entire index at once while the webbing is stationary.

Track feeder for capsules, flat and oblong tablets; consists of a hopper, vibratory chute, vibratory conveyor, and tracks.

The track-roller feeder for flat tablets; consists of a hopper, vibratory chute, tracks, and rolling drum.

After feeding, the clearing brush removes extra capsules from the webbing to prevent them from entering the sealing station.

Integrated product inspection system with a color camera can reject faulty blisters automatically (optional).

The servo-regulated magazines accurately control blister transfer and feeding to assure the stability of high running speed.

The Leaflet Folding Device makes the leaflet fold one to four-folds

The rotary carton feeder pick up cartons then places them in carton conveyor chain.

Innovative design to place the inserting device at the rear; The conventional front-placing design protrudes from the operation side is not ergonomic.

Adopts digital position indicator achieves straightforward adjustment.

At the end of the line, the cartons are discharged automatically.

Tool-free changeover of forming mold.

Tool-free changeover of punching mold.

Adopts aluminum control enclosure and color Touch Screen User Interface.

Main Technical Parameters

| Max. Output: | 500 cartons/min. |

| Range of Carton Size: | Max.: 200x90x60mm Min.: 75x35x15mm |

| Machine Power: | 47kw |

| Machine Dimension: | 1150x1800x2100mm |

| Machine Weight: | 7600kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.