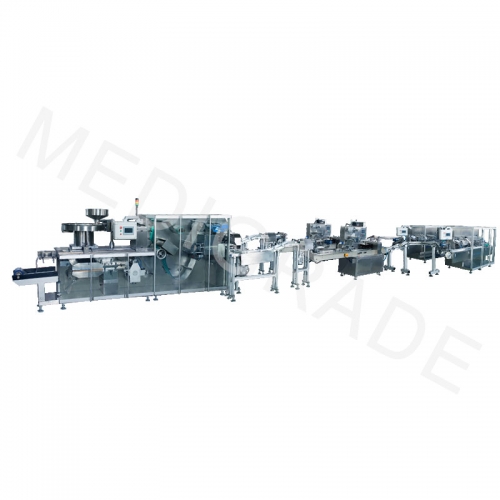

Fully automatic high speed aluminum plastic, 2 pillow bags, high speed cartoning, 3D packaging production line

Sample

Overview

One. Overview of automatic high-speed aluminum plastic, 2 pillow bags, high-speed cartoning, 3D packaging production line:

1. The whole line is designed and manufactured according to the space space of the current GMP standard workshop.

2. Separate design of each functional area of the whole line, using German imported photoelectric eye tracking and detection to automatically control the entire line operation.

3. The movement of each station in the whole line has a very high electronic automatic synchronism, which makes the operation of the whole line more coordinated, more balanced and low noise.

4. This line integrates high-speed aluminum plastic, pillow bag, high-speed cartoning, three-dimensional packaging in one, simple operation. PLC programmable control, touch human-machine interface.

5. High degree of automation, wide control range, high control precision, sensitive control response and good stability.

6. This production line can not only be produced in linkage, but also can be produced in a single machine.

7. The number of parts is small, the structure of the machine is simple, and the maintenance is convenient.

8. Low decibel design, ergonomic application.

9. The high-speed aluminum-plastic, pillowcase, high-speed cartoning and three-dimensional packaging machines are connected by a continuous conveying system to ensure multi-machine linkage.

two. Introduction to the main functions of the machine

Automatic packaging line (DPH320H automatic high speed roller aluminum and plastic blister packaging machine, 2 PW300B pillow packaging machine, XWZ300 continuous high speed cartoning machine, TMB-300 three-dimensional transparent film packaging machine)

2.1. Product Name: Automatic high speed roller aluminum and plastic blister packaging machine

Product model: DPH320H

Product introduction:

DPH320H high-speed roller plate aluminum-plastic blister packaging machine (has obtained national invention patent, patent number: ZL 201010213970.1) is a blister type for medicines (tablets, capsules) food, medical equipment, health care products, electronic components and the like. Special equipment for aluminum (PTP)/plastic (PVC) composite sealing and packaging, due to the use of positive pressure forming, rolling and heat sealing, it has the characteristics of blistering and flattening.

DPH320H high-speed roller aluminum and plastic blister packaging machine is a new generation of products carefully developed and developed by our company. The number of punching times can be up to 200 times per minute, which is about four times higher than that of ordinary blister packaging machines. It combines the advantages of flat and roller blister packaging machines, and is equipped with a special shaped tablet feeder with high punching frequency, energy consumption, accurate and stable operation, convenient mold replacement, high yield, and wrong version. There is no horizontal waste edge punching and other characteristics (about 440,000 annual savings of consumables), and the production efficiency is greatly improved. The design of the whole machine is more reasonable. It adopts the frequency conversion speed regulation and the automatic control technology of machine, electricity, light and gas, and carries out the innovative design strictly according to the requirements of the "GMP" standard of the pharmaceutical industry. The whole machine is divided into groups, and the structure of the station is modular. Many features.

DPH320H high speed roller plate aluminum plastic blister packaging machine performance

1. The forming heating plate is automatically closed and opened. It can be turned on after the heating plate is put down, and the material waste is limited to a range.

2. The air cushion is heat-sealed, and the anilox roller is automatically raised by the cylinder when the machine is stopped. It eliminates the deformation phenomenon of the blister caused by heat radiation during staying, and also facilitates the cleaning work of the anilox roller, and at the same time acts as a buffering function when overpressure, which is beneficial to prolonging the service life of the machine.

3. Rolling heat sealing The blister is filled with tablets and aluminum foil through the two rollers, and the two rollers are in contact with each other to form a line. The contact area is small and the pressure is relatively large, so that the heat sealing is more thorough. The contact area is small and the heating time is short, which makes the speed of the whole machine faster, which is one of the advantages of the heat sealing of the drum. The heat sealing roller is equipped with a stainless steel heating tube for heating the heat sealing roller, and the heating tube is controlled by an automatic temperature control system to make it constant temperature. The roller mold and the heat sealing roller are heated for a long time, and the machine adopts air cooling to avoid water cooling in the past. The phenomenon of water leakage.

4, PVC finish, fragment automatic alarm, stop, and equipped with emergency stop safety device, improve the safety of the operator in debugging and changing the mold.

5, batch number A variety of fonts for you to buy, the machine design batch number of digits to meet customer needs, the strength of the words to make the words clearer, the roller machine synchronization is correct to make the position of the batch number more accurate.

6. All parts and hoppers that come into contact with the drug are made of stainless steel and non-toxic materials, which meet the requirements of "GMP".

7. Servo stepping and punching The rotation angle of the stepping die behind the bubble blowing (that is, the length of the bubble coming out) is consistent with the rotation angle of the stepping die above the die (the length of the bubble that is transferred into the punching), and the plate synchronization is achieved. The plate changes only need to dial the gear, no need to change gears, the wrong version of the edgeless punching makes the vertical waste edge become 1mm, no horizontal waste edge, according to 8 hours per day * 2 production a year can save more than 440,000 yuan of materials, rushed out of the section The orderly arrangement can be launched in a length of 1 meter without the need to manually arrange the plates, which facilitates the next process of cartoning.

8. Start-up operation, the oil pump automatically refuels every 10 minutes (can also set parameters separately) to play the role of lubrication and cooling, protect the smooth operation of the machine and prolong the service life of the machine.

9, machine protection device:

(1) If the PVC is missing and the aluminum foil is missing, the machine will stop automatically.

(2) When the medicine is lacking, the machine will automatically alarm.

(3) The air pressure is insufficient, and the machine automatically stops and stops.

(4) Whenever the temperature exceeds the limit temperature, the machine will automatically cut off the heating system to protect the electronic control system from damage.

(5) The PLC system has help information to make your operation more convenient.

The above fault occurrence touch screen will display the fault condition and the fault point, making it easy for you to troubleshoot.

Product model: PW-300B

PW-300B multi-functional automatic high-speed pillow packaging machine is mainly used for bag packaging of aluminum-plastic packaging plates in medicine, food and other industries, which plays the role of moisture-proof, dust-proof and light-proof, and improves product grade and added value. The machine can save more than 20% of cost compared with manual bag making, and can be produced in conjunction with aluminum-plastic packaging machines and transparent film packaging machines. main feature:

1. The structure is compact and reasonable, the performance is stable and advanced, and the operation is simple and easy to understand;

2, double-conversion motor control, stepless speed change, the bag length is set to cut, no need to adjust the air, one step in place, saving time and film.

3, the use of internationally renowned electrical components, PLC control, man-machine interface, parameter settings are convenient and fast;

4, the fault diagnosis tips at a glance, the use is more user-friendly;

5, high-sensitivity photoelectric eye color tracking, so that the sealing and cutting position is more accurate;

6. The temperature setting is accurate, suitable for various packaging materials, and the sealing quality is improved;

7, with positioning stop function, no sticking knife, no film;

8. The transmission system is simple and clear, the work is more reliable, and the maintenance is more convenient;

9. All control is realized by software, which facilitates function adjustment and technology upgrade, and can meet the production needs of different periods.

10, dispensing plate servo control feeder device, can be suitable for a variety of aluminum plastic plate automatic cutting.

2.3 Product Name: Continuous High Speed Cartoning Machine

Product model: XWZ220

Product introduction:

XWZ220 high-speed cartoning machine is a mechatronics product developed by our company with years of production experience and advanced technology. It is made up of feeding-instruction folding-pill box--drug and manual into box-carton batch number-pill box sealing-finished product It is composed of output and other parts, and adopts automatic control of machine, electricity, light and gas to realize automatic production of pharmaceutical packaging. Advanced detection methods are adopted in each operation link, and unqualified products are automatically removed to ensure the qualified rate of finished products, and human error is controlled to the lowest. The limit effectively prevents the quality of the drug from being contaminated during the packaging process, and ensures that the pharmaceutical packaging production process fully complies with the requirements of GMP, and greatly reduces the production cost and labor intensity.

The XWZ220 high-speed cartoning machine adopts a balcony structure design. The innovative compact design and ergonomic structure allow the operator to get the maximum access to the equipment and clean it. The balcony-type suspended structure of the whole machine will scatter the dirt during the operation of the machine. Dropped from the suspended seam in the uniform collection place under the machine, easy to clean, and the whole body is wrapped in stainless steel, closed circuit, pneumatic structure, making the machine more user-friendly design, the drive device is located at the back of the machine, at the operator The one side is completely open and meets GMP requirements, making it very easy to operate. The innovative compact design and ergonomic construction allow the operator to get the most out of the equipment and clean it, all in one easy operation.

One. Performance characteristics:

1.1. The equipment cover is composed of high quality 304 stainless steel cover and aluminum alloy tempered glass protective door. The aluminum alloy tempered glass protective door is built-in Schneider magnetic switch (certified by CE). When the machine is opened during normal production, the machine will automatically stop working to ensure the safety of the operator.

1.2. The device adopts a horizontal packing box. The paper box is placed in the rotating chain through the suction cup, and the rotating chain is continuously operated in the same direction, and the carton and the medicine are packaged and packed in a lying down manner.

1.3. The whole machine adopts continuous packing, the machine is packed in a stable running state, and the mechanical running noise and load are minimized.

1.4. The medicine into the box adopts the multi-head multi-station boxing mode. When the pusher and the medicine and the carton are in synchronous operation, the pusher uses a linear cam mechanism to feed the medicine into the carton within a certain distance, and the medicine is in any non-impact state. Drop into the box.

1.5. The control system uses the human-machine interface touch screen to dialogue with the machine to realize the adjustment of each station program and the statistics of the machine production status. Fault alarm display and other functions.

1.6, the program uses PLC full automatic monitoring, photoelectric detection mechanism, can carry out the lack of plate loading and automatic display of carton jam, alarm and automatic rejection, to ensure the output of the finished product. And the automatic count is displayed on the screen.

1.7. The main motor adopts frequency conversion speed regulation.

1.8. There is no need to replace the parts when the variety is changed. It can be directly converted by the adjustment mechanism. The adjustment parts are tightened by the adjustable tightening screws. It is easy to operate and can be adjusted without tools.

1.10. All parts in contact with the drug, including the secondary hopper, are made of stainless steel and non-toxic materials and meet the requirements of "GMP".

1.11 Main functions: manual automatic folding (1- 4 fold) conveying; automatic material feeding and feeding; automatic carton unfolding, manual, material automatic cartoning, synchronous printing (three-phase) batch number, carton automatic sealing, waste Automatic rejection.

1.12 Suitable for: blister plates, injection trays, bottles, ointments and rectangular or sheet-like items.

2.3, product name: three-dimensional transparent film packaging machine

Product model: TMB-300

Product introduction:

First, the main features

1. Fully automatic feeding, conveying, stacking, filming, forming, sealing, counting, etc.

2. The machine can be used independently or in combination with laser coders and cartoning machines to form an automatic production line.

3. The use of angled packaging makes the packaging more perfect and improves the anti-counterfeiting ability of the packaged object.

4. During the packaging process, when the small box is supplied, it can be automatically turned on; when there is no small box supply, it will automatically stop.

5. The operation is simple, and different packaging forms can be adopted according to user requirements, and the size can be arbitrarily adjusted within the packaging range.

6. Measuring instruments and meters adopt instruments and meters that meet the legal measurement unit.

7. The machine has compact structure, advanced performance, stable operation, high efficiency, energy saving and stepless speed regulation.

Second, the main technical performance

1. Package size range: L (50~300) × W (40 ~ 220) × H (10 ~ 90) mm;

2. Packing speed: (10~35) medium package / minute;

3. Packaging material: BOPP or PVC;

4. Air consumption: (50~100) L/min;

5. Total power: 2.25KW;

6. Power consumption: 1.5KW;

7. Integrated noise: <65dB(A);

8. Dimensions: 1950mm × 1100mm × 1130mm;

9. Machine weight: 500Kg

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com