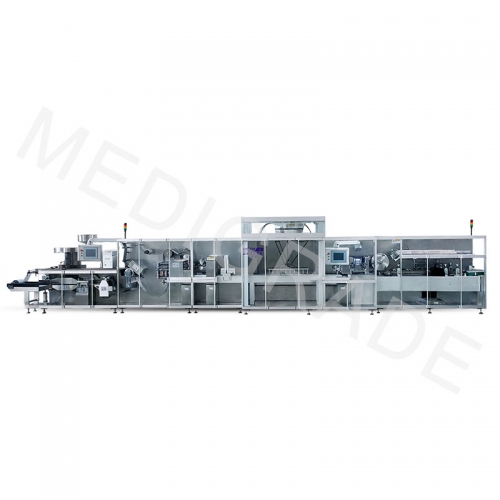

High-speed Blister-Cartoning Link Machine

Sample

The production capacity of DHL600 High-Speed Blister-Cartoning Link Machine can reach 600 blisters/min and 300 cartons/min,suitable for mass production.The whole production line with the concept of advanced technology,original create link machine (1-5) blister cartoning production new pattern,can complete switchover (1-5) blister cartoning within one minute,high speed transferred by intelligent flex picker,complete blister cartoning; Leaflet folder can accomplish 300 pages/min (A4 paper).

Overview

DHL600 high-speed blister-packing machine production line speed up to 600 version / minute blister machine and 300 boxes / minute cartoning machine, suitable for mass production.

The whole production line incorporates the international advanced technology concept, and the new machine (1-5) version of the box production new mode, can complete the (1-5) version of the box in one minute, through the intelligent robot high-speed transfer, complete the blister Packing; manual folding machine can complete A4 paper 500 pages / minute output; man-machine interface can be industrial control network, remote monitoring, complete data transmission, parameter modification, acquisition, storage and printing; high-speed blister boxing machine with balcony The structure is designed and the drive unit is located at the rear of the machine for easy cleaning and GMP compliance.

Innovation

1.DHL600 high-speed blister-packing machine packaging line production line speed up to 600 version / minute blister machine and 300 boxes / minute cartoning machine, suitable for mass production, through the robot transfer device to push the grille in the conveyor belt The method of directly stacking in the carton bin is more than the original blister flat belt conveyed into the magazine and then servoed into the bin of the cartoning machine. The output is turned over and the stability is more reliable.

2. The entire blister packaging production line incorporates international advanced technology concepts, and the design is based on mature technology, achieving high efficiency of the entire packaging process. DHL600 high-speed blister-packing machine is different from other models in that it integrates the advantages of the existing high-speed blister packaging machine and cartoning machine. High-speed production ensures fast mold replacement and cleaning is the largest in the production line. Highlights.

3. Three rows of blister board grille push plate transport storage area and robot synchronous transfer to the cartoning machine bin loading box (bubble plate grid spacing is the same as the boxing machine silo spacing), not only the output has been turned over Turning, stability can be more reliable.

4. The continuous rotary suction plate device sucks the punching block to the three rows of blister plate grill storage area and then transfers the blister board to the special transmission system on the side of the carton bin, and the three rows are arranged by the intelligent robot. The blister plate grill storage area blister plate is sucked into the carton bin, and sequentially sucks three rows of blister plate grill storage area, three rows of blister plates 3*8=24 plates/time, and keeps the blister The packaging machine runs synchronously with the cartoning machine, ensuring high performance of the entire production line. (2 version/box as an example, set the number of blister machine version 600 version / minute, automatically match the number of boxing machine box 300 boxes / minute, the robot sucks three rows of blister version grille storage area three rows, eight columns To realize the stacking of the 2nd version in the carton bin, the robot tracks the synchronization interval of the two device encoders, so that the plates can be synchronously transferred between different devices, 1 version/box, 3 version/box, 4 version/box, 5 version/box Set the corresponding parameters of the two devices, the principle of mechanical suction and discharge is the same as above).

5. The blister packaging machine and the cartoning machine are completely designed with balcony structure. The innovative compact design and ergonomic structure allow the operator to get the maximum access to the equipment and clean it. The blister packaging machine and the cartoning machine are completely The balcony structure design, the balcony-type suspended structure of the whole machine, the scattered dirt in the machine running, will fall from the suspended seam to the uniform collection place under the machine, convenient for cleaning, stainless steel wrapped body, closed circuit, gas path structure, The machine is more user-friendly, the drive is located at the rear of the machine, completely open on the operator side, in line with GMP requirements, very easy to operate. The innovative compact design and ergonomic construction allow the operator to get the most out of the equipment and clean it, all in one easy operation.

6. The all-in-one machine can complete the (1-5) version of the new production mode task operation by changing the man-machine interface parameters. Thanks to the simple operation and friendly man-machine interface, a number of production operations can be completed. The same specification section is completed in 1 version/box, 2 version/box, 3 version/box, 4 version/box, 5 version/box By changing the man-machine interface parameters, the 1-5 version of the box can be switched, and there is no need to replace the parts on the equipment. Although the production line is a high-speed large-scale production line, the mold replacement time is short and the cleaning convenience is also effectively guaranteed.

7. The second inspection of the cartoning machine guarantees 100% finished product output. After the robot completes the stacking, the plate in the silo passes the rotary material level detecting device, and meets the required parameter number of the silo, suction manual, suction carton After the completion of the road box, does not meet the requirements, do not suck the instructions, do not suck the carton, so that the plate is transported to the unpacked finished product collection bin, after a level of material inspection and then after the cartoning process, the implementation of the secondary level detection, through Capacitive optical eye detection conforms to the output of the set pressure box conveying device, and does not meet the setting requirements and is removed by the box removing device.

8. The folding machine can complete the A4 paper output of 500 pages/minute.

9. The man-machine interface can be industrially controlled, remotely monitored, and complete data transmission, parameter modification, acquisition, storage and printing.

10. Separate design of each functional area of the whole line, using German imported photoelectric eye tracking and detection to automatically control the entire line operation.

11. The operation of each station in the whole line has extremely high electronic automatic synchronization, which makes the operation of the whole line more coordinated and balanced, the structure of the machine is simple, the maintenance is convenient, the low-decibel design and the ergonomics application.

12. This line is equipped with high-speed blister packaging machine and high-speed cartoning machine. It is easy to operate. PLC programmable control, touch human-machine interface.

13. High degree of automation, wide control range, high control precision, sensitive control response and good stability.

14. The equipment cover is composed of high quality 304 stainless steel cover and aluminum alloy tempered glass protective door. The aluminum alloy tempered glass protective door is built-in Schneider magnetic switch (certified by CE). When the machine is opened during normal production, the machine will automatically stop working to ensure the safety of the operator.

Min Technical Parameter

|

capacity (Blisters/min ) |

300-600 Blisters/min |

|

|

Range of stroke(mm) |

20-120 |

|

|

Packing material |

Pharmacy PVC (mm) |

(0.2-0.4)x320 |

|

PTP alu foil (mm) |

(0.02-0.05)x320 |

|

|

Capacity (Cartons/min) |

100-300 carton/min |

|

|

Packing material: |

Box dimension (LxWxH) (mm) |

(70-190)x(35-75)x(15-70) |

|

Cardboard of box required (g/m²) |

300-350 |

|

|

Leaflet dimension (LxW) |

(100-260)x(100-190) |

|

|

Leaflet pap required (g/m²) |

50~70 |

|

|

Clean compressed air (pressure) |

0.5-0.7 Mpa |

|

|

Air consumption (m³/h) |

≥0.6 |

|

|

Power |

AC380V 50HZ 27KW |

|

|

Water chiller for moulds |

1.5P with 60L/h consumption |

|

|

Overall dimension (LxWxH)(mm) |

11000 x 1800 x 2150 |

|

|

Net Weight |

9200kg |

|

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com