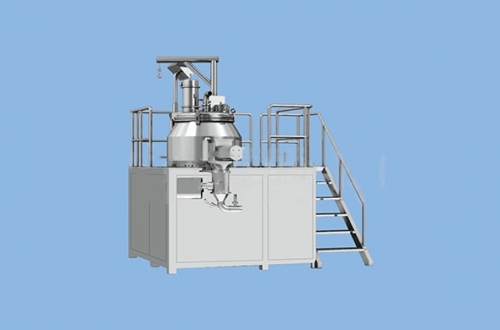

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has such functions as mixing, granulating, etc. It has been widely used in such industries as medicine, food, chemical industry, etc.

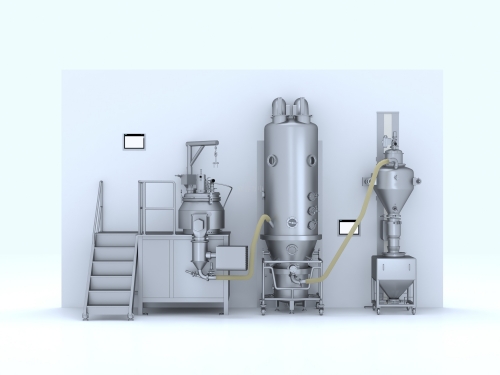

The Closed granulation line is mainly used in the powder granules of the pharmaceutical,food,chemical and other industries,which can inhibit the dust leakage and pollution generated during the process of material transfer,posing a threat to people and the

The mixer is featured by simple mixing, unique structure, high efficiency. no dead angle and even mixing.

1. Development of water dispersible granules (WDG) for pesticide industry.

2, The pharmaceutical industry granules

3, Chicken essence and other condiments in the food industry with granules.

4, The food industry oral granules.

5, Particles in the chem

The powder material and adhesive are fully mixed into wet and soft materials by the bottom mixing paddle in a cylinder (cone) container, and then cut into uniform wet particles by the side high speed grinding paddle.

This machine is a fluidization dryer. It is the use of hot air and material full contact to take away the water, so as to achieve drying a dryer, is a dynamic drying equipment. Temperature control probe is equipped at the air outlet to measure the tempera

FDV air-led pulverizer is a kind of equipment which realizes fine crushing of dry materials by means of high-speed rotating impact of pulverizing blade and separation of air flow whirlwind. It is composed of feeding port, aggregate tank, crushing chamber,

MDLB is a mini granulator for research and development. The formability of the machine can be easily discovered, and the data of scale-up proportion can be obtained by using only nearly300powder lot. Besides, roller and propeller can be replaced in a shor

The machine is provided with a degas feeding propeller, a compressive former roll, apressurizing mechanism, a control mechanism, vessels, etc. It can be easily dissembled and cleaned, and is in accordance with GMP standards. For the heat sensitive materia

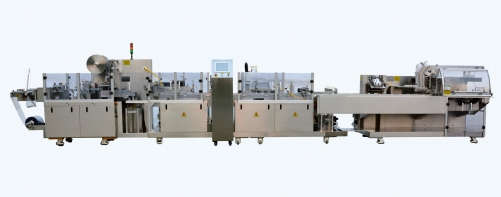

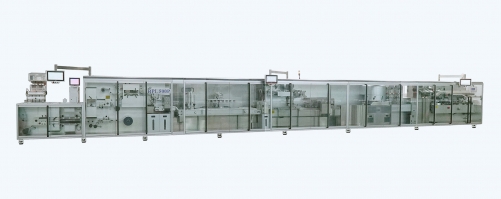

This Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for medium batch production.

. Adopt various robot feeders for packaging of ampoules, vials, oral liquid, and

Through the integration of a blister and cartoner module for packaging and cartoning of pharmaceutical ampoules, vials, oral liquid, and syringe, etc.

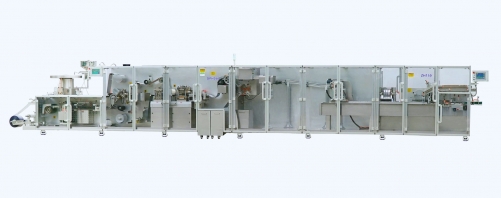

This type of Blister Machine adds one tropical aluminum forming station and a second sealing station to allow the plastic thermoforming blister package to be sealed with formed tropical aluminum again.

This line integrated a pillow packing unit after the blistering unit, to allow the plastic thermoforming blister package to be sealed again by laminated film that offers a nearly complete barrier for water, light, and oxygen, allowing an extended product

The machine can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and a waste material trimming cutter.

The heart of a Blister Line is the connection between the Blister Machine and Cartoner. In this line, the connection phase is truly innovative thanks to a servo-regulated robot that picks up blister cards and transfers them to the cartoning machine synchr