Blister Line BPL100 (compact)

Brief introduction

The blister magazine in the cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted and when they free fall, are then held in position by the transfer belt.

Description

Customer Case

Featured Products

These days, pharmaceutical packaging systems must fulfill this market requirement: the volumes of batches are decreasing and the number of variations is increasing, which leads to frequent format change-overs and cleaning.

This Blister Line is our latest innovative response to this market need.

. The integration of Blister Packaging and Cartoning systems achieves high efficiency and low-cost operation.

. Flexible and straightforward for multi-variety and small batch production.

. Optimally combined to form a compact line only five meters in length enabling installation in small production space.

. The output equals 120 blisters and 100 cartons per minute – offering a maximum blister size of 135×120 mm and a carton format of up to 150x115x50mm.

. Central operation via touch-screen system.

. Blister feeder (universal or dedicated), which feeds standard shaped products quickly and efficiently.

. After filling, a color camera subsequently checks the products – it can reject faulty blisters automatically (optional), and only perfect blisters are transferred to the cartoner unit.

. Sealing of the blisters is carried out by a device that combines pneumatic and hydro form advantages that can easily adjust sealing pressure. When the machine stops, the heat sealing mold can rise up automatically to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

. The material traction system uses a precise servo motor to achieve stable, accurate running. The blister length can be set freely through the Touch Screen User Interface, which reduces the time for a format changeover.

. The blister transfer mechanism uses suction arms and takes the blister cards from the punch station, and gently forwards them to the transfer conveyor.

. The blister magazine in the cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted and when they free fall, are then held in position by the transfer belt.

. The leaflets are isolated from the bottom of a pile magazine, then pulled off and folded. Leaflets can be folded from one to four folds, according to the customer’s requirements.

. In case there are no cartons and/or no blister cards, the leaflet folder will be automatically be suspended without stopping the machine – a new leaflet is then ready to be inserted in the good carton.

. The inserter device can push the blister cards and leaflets into the carton.

. In the carton conveyor chain, the cartons are closed automatically. By using the digital position indicator straightforward adjustments are achieved

. The carton closing station is for tuck-in and the hot-melt unit can also be integrated into the cartoner.

. Thanks to its toolless size-changing the machine production times are increased and the machine idle times are reduced.

. The change-over can be carried out by the operator with a simple and fast procedure due to simple, fixed-position parts, digital indicators for the adjustments, and complete accessibility.

. The Blister Line adopts a transparent cover which assures safe operation. All areas of the line are visible so operating personnel can keep an eye on the production steps.

Gallery

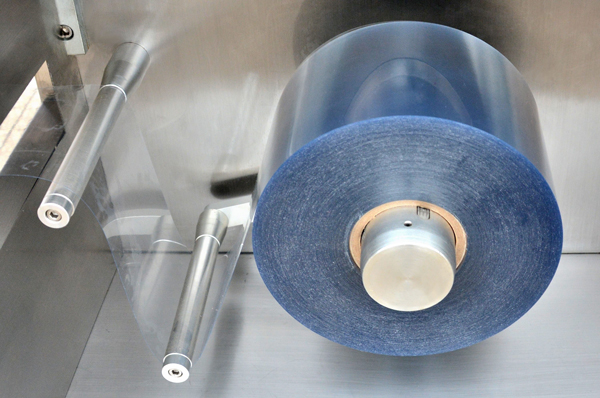

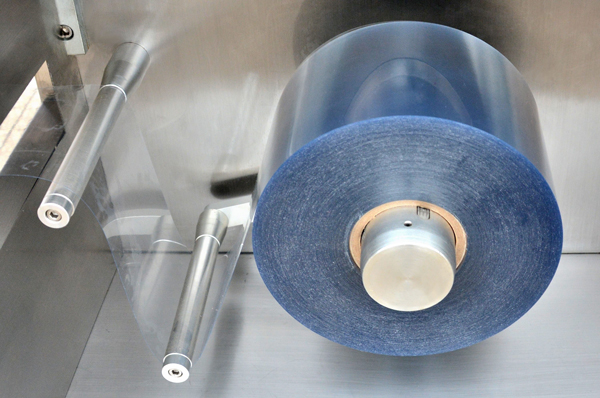

Forming material reel of the Blister Machine.

The Forming Station adopts contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

Blister feeder (universal or dedicated), which feeds standard shaped products quickly and efficiently.

The forming station and feeding area.

Central operation via touch-screen system.

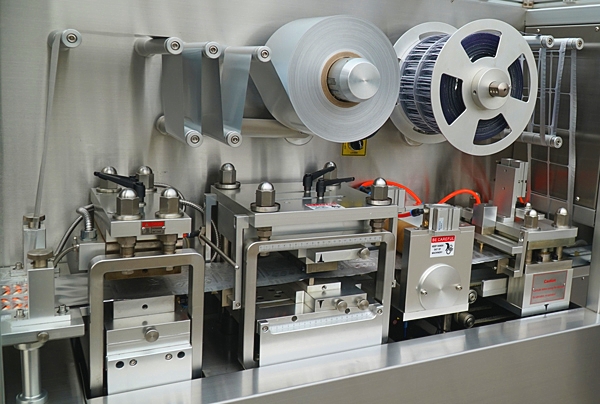

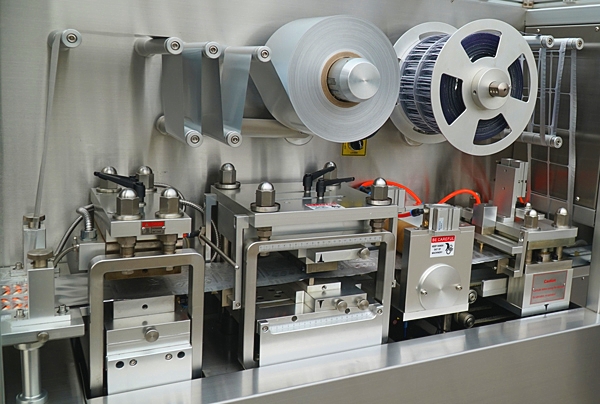

The lidding material reel adopts a fast lock mechanism, enabling replacement of lidding material easily within about 10 seconds.

The sealing station can easily adjust the sealing pressure. When the machine stops, the heating sealing mould can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

The material drag system adopts a precise servo motor to achieve stable, accurate running. The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

The sealing station, embossing station, web index and waste material winding mechanism.

The blister transfer mechanism adopt suction arms, it take blister cards from the punch station and gently forward them to the transfer conveyor.

The blister magazine in cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted when they free fall, and are then held in position by the transfer belt.

The Leaflet are isolated from the botton from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand.

In case of no carton and/or no blister cards, the leaflet folder will be automatically suspended without stopping the machine and a new leaflet is ready to be inserted in the good carton.

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment.

The carton closing station for tuck-in, hot-melt unit can also be integrated into the cartoner.

The change-over can be carried out by the operator with easy and fast procedure in a time, by simple fixed-position parts, digital indicators for the adjustments and complete accessibility.

Taking the mold from the stations easily, achieve straightforward changeovers.

The Blister Line adopt transparent cover assures safe operation. All areas of the line are visible so operating personnel can keep an eye on the production steps.

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

This Blister Line is our latest innovative response to this market need.

. The integration of Blister Packaging and Cartoning systems achieves high efficiency and low-cost operation.

. Flexible and straightforward for multi-variety and small batch production.

. Optimally combined to form a compact line only five meters in length enabling installation in small production space.

. The output equals 120 blisters and 100 cartons per minute – offering a maximum blister size of 135×120 mm and a carton format of up to 150x115x50mm.

. Central operation via touch-screen system.

. Blister feeder (universal or dedicated), which feeds standard shaped products quickly and efficiently.

. After filling, a color camera subsequently checks the products – it can reject faulty blisters automatically (optional), and only perfect blisters are transferred to the cartoner unit.

. Sealing of the blisters is carried out by a device that combines pneumatic and hydro form advantages that can easily adjust sealing pressure. When the machine stops, the heat sealing mold can rise up automatically to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

. The material traction system uses a precise servo motor to achieve stable, accurate running. The blister length can be set freely through the Touch Screen User Interface, which reduces the time for a format changeover.

. The blister transfer mechanism uses suction arms and takes the blister cards from the punch station, and gently forwards them to the transfer conveyor.

. The blister magazine in the cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted and when they free fall, are then held in position by the transfer belt.

. The leaflets are isolated from the bottom of a pile magazine, then pulled off and folded. Leaflets can be folded from one to four folds, according to the customer’s requirements.

. In case there are no cartons and/or no blister cards, the leaflet folder will be automatically be suspended without stopping the machine – a new leaflet is then ready to be inserted in the good carton.

. The inserter device can push the blister cards and leaflets into the carton.

. In the carton conveyor chain, the cartons are closed automatically. By using the digital position indicator straightforward adjustments are achieved

. The carton closing station is for tuck-in and the hot-melt unit can also be integrated into the cartoner.

. Thanks to its toolless size-changing the machine production times are increased and the machine idle times are reduced.

. The change-over can be carried out by the operator with a simple and fast procedure due to simple, fixed-position parts, digital indicators for the adjustments, and complete accessibility.

. The Blister Line adopts a transparent cover which assures safe operation. All areas of the line are visible so operating personnel can keep an eye on the production steps.

Gallery

Forming material reel of the Blister Machine.

The Forming Station adopts contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

Blister feeder (universal or dedicated), which feeds standard shaped products quickly and efficiently.

The forming station and feeding area.

Central operation via touch-screen system.

The lidding material reel adopts a fast lock mechanism, enabling replacement of lidding material easily within about 10 seconds.

The sealing station can easily adjust the sealing pressure. When the machine stops, the heating sealing mould can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

The material drag system adopts a precise servo motor to achieve stable, accurate running. The blister length can be set freely through Touch Screen User Interface, which reduces the time for a format changeover.

The sealing station, embossing station, web index and waste material winding mechanism.

The blister transfer mechanism adopt suction arms, it take blister cards from the punch station and gently forward them to the transfer conveyor.

The blister magazine in cartoner unit is carried out by a servo- motor. Inside the magazine, the blister cards are counted when they free fall, and are then held in position by the transfer belt.

The Leaflet are isolated from the botton from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand.

In case of no carton and/or no blister cards, the leaflet folder will be automatically suspended without stopping the machine and a new leaflet is ready to be inserted in the good carton.

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment.

The carton closing station for tuck-in, hot-melt unit can also be integrated into the cartoner.

The change-over can be carried out by the operator with easy and fast procedure in a time, by simple fixed-position parts, digital indicators for the adjustments and complete accessibility.

Taking the mold from the stations easily, achieve straightforward changeovers.

The Blister Line adopt transparent cover assures safe operation. All areas of the line are visible so operating personnel can keep an eye on the production steps.

Main Technical Parameters

| Max. Output: | 100 cartons/min. |

| Range of Carton Size: | Max.: 150x115x50mm Min.: 70x25x15mm |

| Machine Power: | 10kw |

| Machine Dimension: | 5000x1100x1800mm |

| Machine Weight: | 3000kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.