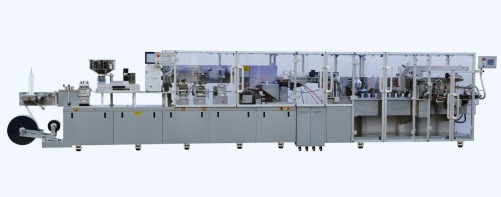

Blister Line BPL120

Brief introduction

This Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for medium batch production

Description

Customer Case

Featured Products

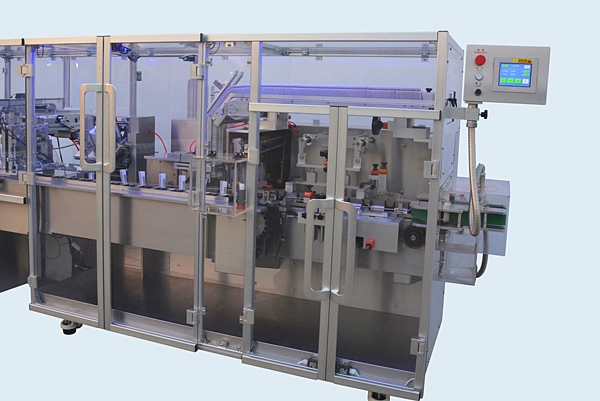

This Blister-Cartoner Line is combined with the DPP260Ki2 Blister Machine and ZH120i Cartoner.

Through the integration of a blister and cartoner module for packaging and cartoning of pharmaceutical tablets, capsules, and ampoules, this Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for small and medium batch production.

·Processes all common solid dose products and all types of forming material.

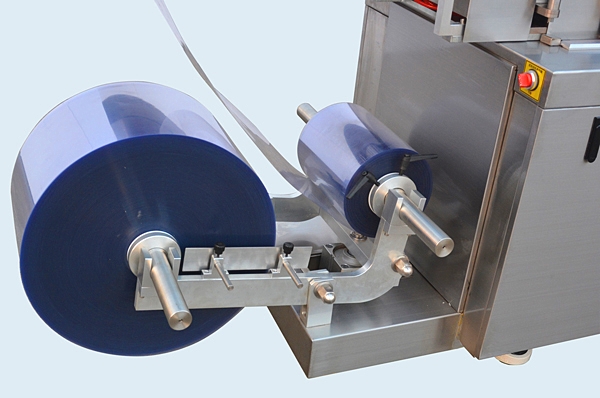

·The machine can achieve 180 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and waste material trimming cutter (optional).

·Capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

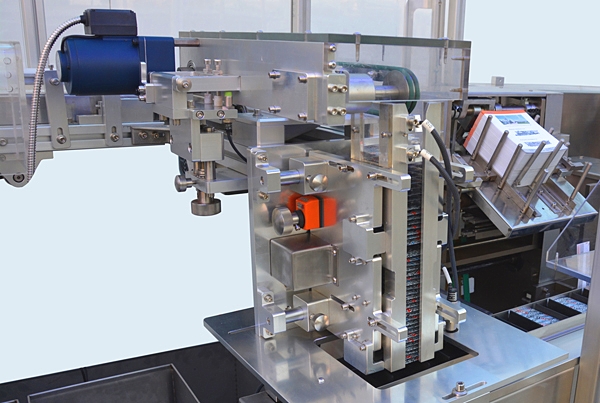

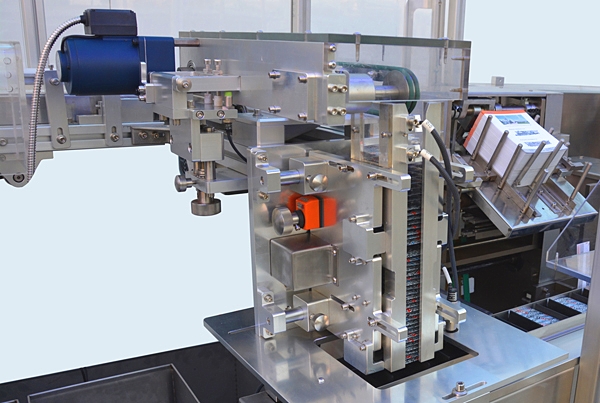

·The heart of a Blister Line is the connection between the Blister Machine and Cartoner. In this line, the connection phase is truly innovative thanks to two vacuum arms and the blister counting magazine that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

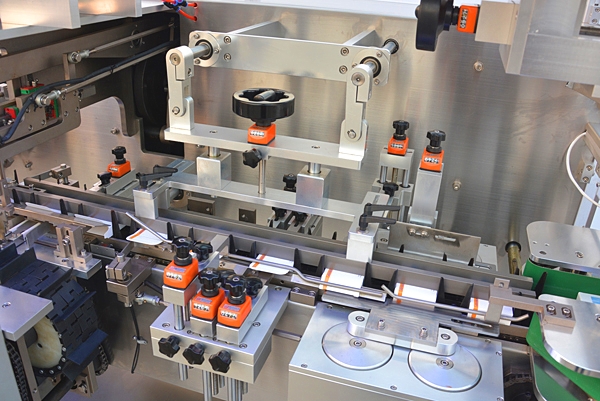

·Since this Line adopts a transfer belt to connect the Blister Machine and Cartoner, it provides easy changeover for different sizes of formats and cartons.

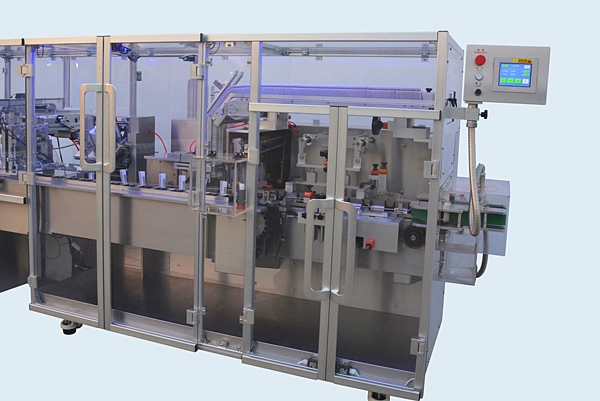

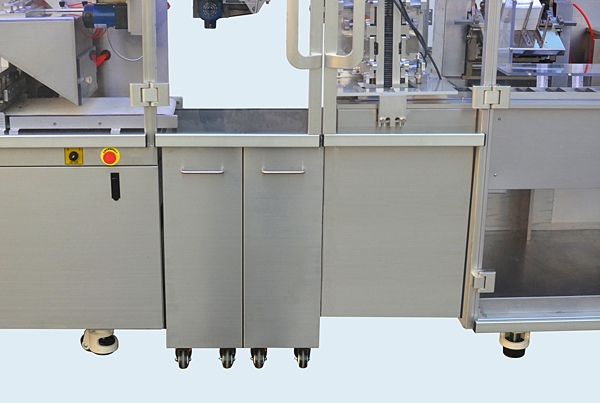

·This line adopts the fully-enclosed structure and safety door, it is in line with the stringent safety standards.

Gallery

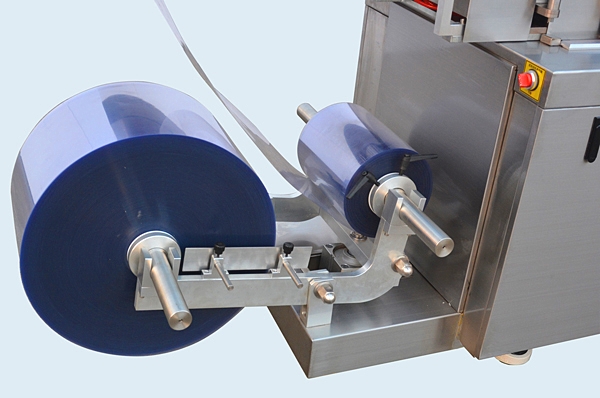

The forming material reel of up to 600mm in diameter.

Equipped with integrated forming material splicer.

The upper and lower plates adopt contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

The contact forming heating station can be opened up conveniently for cleaning.

Equipped with automatic format locking, positioning system, achieves extremely straightforward format changeover.

The universal feeder is capable of feeding almost all items such as capsules, flat tablets, oval tablets, capsule tablets, triangular tablets or other various shapes.

Integrated product inspection system with color camera can reject faulty blisters automatically (optional).

The lidding material loader adopts a fast lock mechanism, enabling replacement of lidding material easily within about 10 seconds.

All of the guide rollers are labeled with a sequence number and placement direction, making it very easy to guide the film and lid foil through the machine.

There are two waste tanks collect waste material alternatively

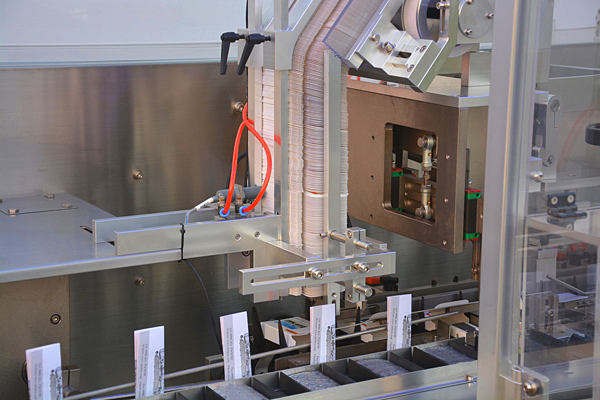

Inside the magazine, the blister cards are counted when they free fall via the servo- motor, and are then held in position by the transfer belt.

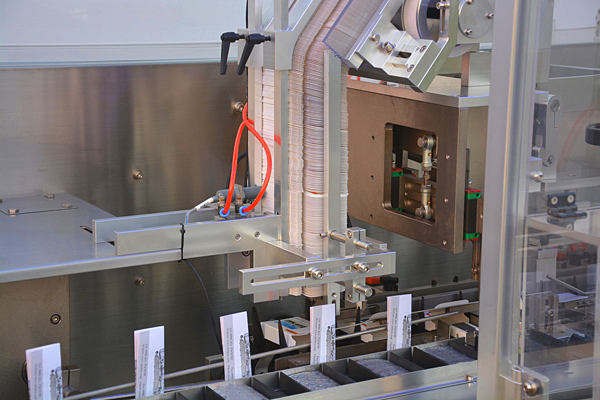

The Leaflet are isolated from the botton from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand.

The inserter device can push the blister cards and leaflet into the carton.

Long carton magazine approximately accommodate 1000 cartons.

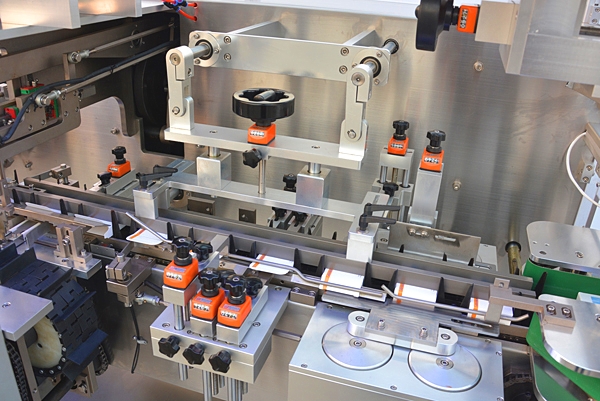

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment.

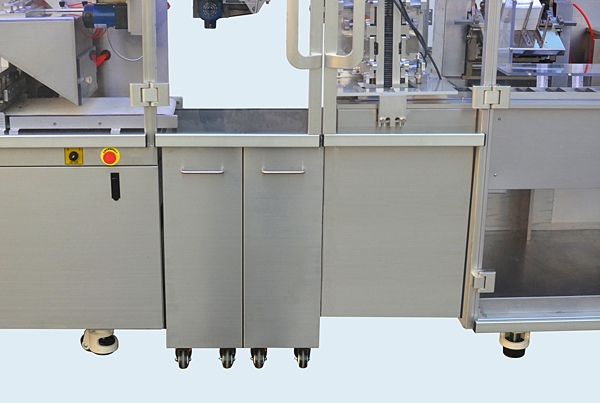

The Blister Line adopt transparent cover assures safe operation.

Main Technical Parameters

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Through the integration of a blister and cartoner module for packaging and cartoning of pharmaceutical tablets, capsules, and ampoules, this Blister Packaging Line is innovative response to the need for high efficiency and low-cost operation, flexibility, and maximum productivity for small and medium batch production.

·Processes all common solid dose products and all types of forming material.

·The machine can achieve 180 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and waste material trimming cutter (optional).

·Capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

·The heart of a Blister Line is the connection between the Blister Machine and Cartoner. In this line, the connection phase is truly innovative thanks to two vacuum arms and the blister counting magazine that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

·Since this Line adopts a transfer belt to connect the Blister Machine and Cartoner, it provides easy changeover for different sizes of formats and cartons.

·This line adopts the fully-enclosed structure and safety door, it is in line with the stringent safety standards.

Gallery

The forming material reel of up to 600mm in diameter.

Equipped with integrated forming material splicer.

The upper and lower plates adopt contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

The contact forming heating station can be opened up conveniently for cleaning.

Equipped with automatic format locking, positioning system, achieves extremely straightforward format changeover.

The universal feeder is capable of feeding almost all items such as capsules, flat tablets, oval tablets, capsule tablets, triangular tablets or other various shapes.

Integrated product inspection system with color camera can reject faulty blisters automatically (optional).

The lidding material loader adopts a fast lock mechanism, enabling replacement of lidding material easily within about 10 seconds.

All of the guide rollers are labeled with a sequence number and placement direction, making it very easy to guide the film and lid foil through the machine.

There are two waste tanks collect waste material alternatively

Inside the magazine, the blister cards are counted when they free fall via the servo- motor, and are then held in position by the transfer belt.

The Leaflet are isolated from the botton from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand.

The inserter device can push the blister cards and leaflet into the carton.

Long carton magazine approximately accommodate 1000 cartons.

In carton conveyor chain the cartons are closed automatically. Adopts digital position indicator achieves straightforward adjustment.

The Blister Line adopt transparent cover assures safe operation.

Main Technical Parameters

| Max. Output: | 120cartons/min. |

| Range of Carton Size: | Max.: 180x85x60mm Min.: 75x35x15mm |

| Machine Power: | 12kw |

| Machine Dimension: | 8400x1100x1800mm |

| Machine Weight: | 3000kg |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.