Flat Type AL/PL、AL/AL Blister Packing Machine(DPP260TI)

Brief introduction

Fission Combination Structure: accessible to elevators or renovated clean workshops. Length of stroke by digital control,running speed directly set on human-machine interface according to the material feeding.

Description

Customer Case

Featured Products

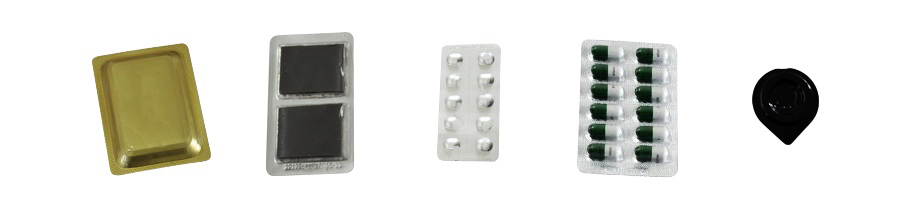

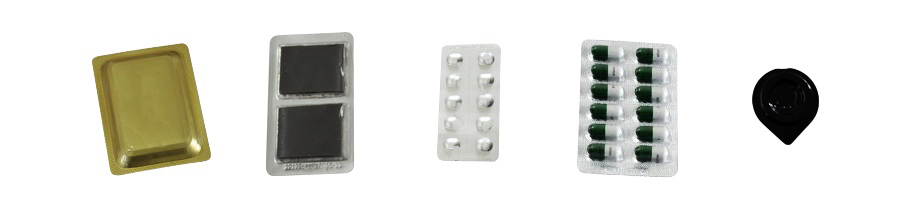

Sample

Fission Combination Structure: accessible to elevators or renovated clean workshops. Length of stroke by digital control,running speed directly set on human-machine interface according to the material feeding.

Missing Pills Rejection Device、Printing Register Control.

Overview

The flat blister packaging machine is a special equipment for blister-type aluminum/plastic and aluminum/aluminum (PTP) composite sealed packaging for medicines (tablets, capsules, ampoules), medical equipment and the like, which is formed by positive pressure forming. , flat pressure heat seal, so it has the characteristics of blister blister, flat plate and so on, which is favored by the industry.

The DPP series automatic aluminum-plastic/aluminum-aluminum blister packaging machine produced by our company adopts frequency conversion speed regulation and automatic control technology of machine, electricity, light and gas, and carries out innovative design strictly according to the requirements of “GMP” standard of pharmaceutical industry. This series of models has many functions such as inspection and rejection, photoelectric photo-automatic photoelectric image-to-plate, adjustable stroke, complete machine split combination, station structure modularization, aluminum/plastic-aluminum/aluminum dual-use, etc. The sixth generation of products. This series of models has been continuously improved and updated by the company, and it is more practical and economical compared with imported equipment.

The company is equipped with professional technical support and after-sales service, and delegates technical personnel to the customer enterprise for machine debugging, technical guidance and personnel training.

Innovation

1. This machine has the function of two-purpose aluminum-aluminum-tantalum-aluminum-plastic machine. The whole machine can be transported separately in separate packaging. It is connected by positioning pin and bolted for easy assembly.

2. The mold adopts the pressure plate clamping; when the forming mold and the heat sealing mold are installed, it is not necessary to adjust the parallel and left and right movements, and the mold changing is more convenient.

3. The machine is designed to punch horizontally without scrapping, and the material cost can be saved by about 29,300 yuan per year (aluminum plastic).

4. After the punching of the medicine plate (finished product), the ejector rod is used to assist the cutting, so that the medicine plate can be smoothly discharged every time the equipment is punched, and the safety hazard of the operator is eliminated.

5. The work surface is lengthened and the operation is smoother.

6. The main engine adopts frequency conversion speed regulation: according to the length of the stroke and the difficulty of filling the filling material, etc., the corresponding number of punching times can be set, and the low-speed debugging can be performed, and after the proficiency, the corresponding high-speed operation can be achieved within a certain range.

7. The robot is used to clamp the feeding mechanism: the stroke can be arbitrarily adjusted from (40-120mm), that is, the size of the plate can be freely designed within this range.

8. The forming heating plate is automatically closed, which limits the waste of plastic to one version. The compression of the plate is used to shorten the heating length of the plastic sheet, reduce the heating power and temperature, thereby enhancing the stability of the plastic sheet.

9. Air cushion heat sealing: When the machine is stopped, the cylinder plate is automatically raised by the cylinder. The deformation phenomenon caused by the heat radiation when the blister is stopped is eliminated, which facilitates the cleaning work of the anilox plate and at the same time acts as a buffer for the super pressure. Conducive to extending the life of the machine.

10. Upper and lower netting male and female with heat sealing: both sides of the front and back are point-like netting (also can be line-sealed), because the stress is equal, the plate curling phenomenon is avoided, and the sealing performance is improved.

11. With two combination feeder: its filling rate can reach more than 99%, eliminating the abnormal shape and filling and missing film caused by high-speed operation.

12. There is a tab (PVC) station to make it easier to pick up the sheet after the sheet is finished or broken.

13. When the machine is packaged with aluminum and aluminum, different types of special feeders can be choose according to different tablets and capsules. Optional feeders such as: rotary vibration track blanking type, push plate type, inclined screen type, capsule filling and control type, etc.

14. The transmission area below the equipment and the upper operation area are completely sealed by stainless steel plates, which avoids cross-contamination between the two sections when the equipment is working, which is more convenient for cleaning.

15. The batch number station is printed by heating, and the writing is clear and clear.

16. It has good mechanical properties, stable transmission, reasonable precision, low noise, no obvious vibration and abnormal thermal deformation.

17. All materials in contact with drugs or packaging materials meet GMP requirements. The exterior of the equipment is made of 304 stainless steel. The heat sealing and punching stations are made of transparent plexiglass shield, which is good for observing and enhancing the safety of operators.

18. The equipment is emergency stop safety device, which improves the safety of the operator in debugging and changing the mold.

19. It has a one-stop assembly line such as electronic counting, batch number, indentation tangent, blanking and automatic shutdown alarm for finished pieces. The process is smooth and the production process is instinct.

Min Technical Parameter

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Fission Combination Structure: accessible to elevators or renovated clean workshops. Length of stroke by digital control,running speed directly set on human-machine interface according to the material feeding.

Missing Pills Rejection Device、Printing Register Control.

Overview

The flat blister packaging machine is a special equipment for blister-type aluminum/plastic and aluminum/aluminum (PTP) composite sealed packaging for medicines (tablets, capsules, ampoules), medical equipment and the like, which is formed by positive pressure forming. , flat pressure heat seal, so it has the characteristics of blister blister, flat plate and so on, which is favored by the industry.

The DPP series automatic aluminum-plastic/aluminum-aluminum blister packaging machine produced by our company adopts frequency conversion speed regulation and automatic control technology of machine, electricity, light and gas, and carries out innovative design strictly according to the requirements of “GMP” standard of pharmaceutical industry. This series of models has many functions such as inspection and rejection, photoelectric photo-automatic photoelectric image-to-plate, adjustable stroke, complete machine split combination, station structure modularization, aluminum/plastic-aluminum/aluminum dual-use, etc. The sixth generation of products. This series of models has been continuously improved and updated by the company, and it is more practical and economical compared with imported equipment.

The company is equipped with professional technical support and after-sales service, and delegates technical personnel to the customer enterprise for machine debugging, technical guidance and personnel training.

Innovation

1. This machine has the function of two-purpose aluminum-aluminum-tantalum-aluminum-plastic machine. The whole machine can be transported separately in separate packaging. It is connected by positioning pin and bolted for easy assembly.

2. The mold adopts the pressure plate clamping; when the forming mold and the heat sealing mold are installed, it is not necessary to adjust the parallel and left and right movements, and the mold changing is more convenient.

3. The machine is designed to punch horizontally without scrapping, and the material cost can be saved by about 29,300 yuan per year (aluminum plastic).

4. After the punching of the medicine plate (finished product), the ejector rod is used to assist the cutting, so that the medicine plate can be smoothly discharged every time the equipment is punched, and the safety hazard of the operator is eliminated.

5. The work surface is lengthened and the operation is smoother.

6. The main engine adopts frequency conversion speed regulation: according to the length of the stroke and the difficulty of filling the filling material, etc., the corresponding number of punching times can be set, and the low-speed debugging can be performed, and after the proficiency, the corresponding high-speed operation can be achieved within a certain range.

7. The robot is used to clamp the feeding mechanism: the stroke can be arbitrarily adjusted from (40-120mm), that is, the size of the plate can be freely designed within this range.

8. The forming heating plate is automatically closed, which limits the waste of plastic to one version. The compression of the plate is used to shorten the heating length of the plastic sheet, reduce the heating power and temperature, thereby enhancing the stability of the plastic sheet.

9. Air cushion heat sealing: When the machine is stopped, the cylinder plate is automatically raised by the cylinder. The deformation phenomenon caused by the heat radiation when the blister is stopped is eliminated, which facilitates the cleaning work of the anilox plate and at the same time acts as a buffer for the super pressure. Conducive to extending the life of the machine.

10. Upper and lower netting male and female with heat sealing: both sides of the front and back are point-like netting (also can be line-sealed), because the stress is equal, the plate curling phenomenon is avoided, and the sealing performance is improved.

11. With two combination feeder: its filling rate can reach more than 99%, eliminating the abnormal shape and filling and missing film caused by high-speed operation.

12. There is a tab (PVC) station to make it easier to pick up the sheet after the sheet is finished or broken.

13. When the machine is packaged with aluminum and aluminum, different types of special feeders can be choose according to different tablets and capsules. Optional feeders such as: rotary vibration track blanking type, push plate type, inclined screen type, capsule filling and control type, etc.

14. The transmission area below the equipment and the upper operation area are completely sealed by stainless steel plates, which avoids cross-contamination between the two sections when the equipment is working, which is more convenient for cleaning.

15. The batch number station is printed by heating, and the writing is clear and clear.

16. It has good mechanical properties, stable transmission, reasonable precision, low noise, no obvious vibration and abnormal thermal deformation.

17. All materials in contact with drugs or packaging materials meet GMP requirements. The exterior of the equipment is made of 304 stainless steel. The heat sealing and punching stations are made of transparent plexiglass shield, which is good for observing and enhancing the safety of operators.

18. The equipment is emergency stop safety device, which improves the safety of the operator in debugging and changing the mold.

19. It has a one-stop assembly line such as electronic counting, batch number, indentation tangent, blanking and automatic shutdown alarm for finished pieces. The process is smooth and the production process is instinct.

Min Technical Parameter

| Capacity (Cycle/min ) | AL/PL≤60 AL/AL≤40 | |

| Packing material: | Range of stroke(mm) | 40-120 |

| Pharmacy PVC (mm) | (0.2-0.5)x260 | |

| PTP alu foil (mm) | (0.02-0.05)x260 | |

| Clean compressed air (pressure) | 0.5~0.7Mpa | |

| Air consumption(m³min) | ≥0.3 | |

| Power | AC380V 50HZ 9KW | |

| Water chiller for moulds | Top water or recycle water with 60L/h consumption | |

| Overall dimension (LxWxH)(mm) | 4420 x 710 x 1700 | |

| Net Weight | 1700kg | |

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.

Thanks to rotary sealing style (alu-pvc) and larger tropical aluminum forming and sealing area, the machine archives high output, for the size of 98mm*70mm, the output can up to 180 blister cards/minute (DPH260H3) and 270 blister cards/minutes (DPH350H3).