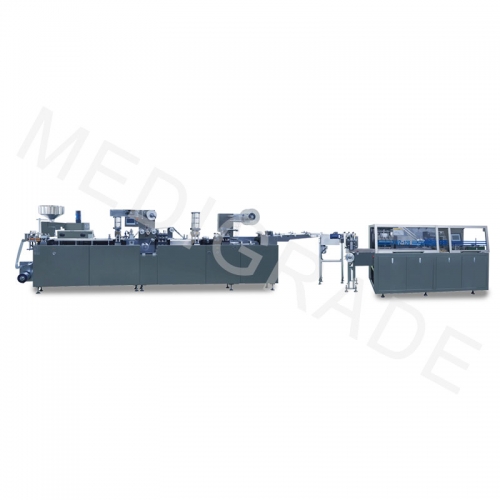

The Auto Tropical Blister-Carton Packaging Line (DPP250FII-XWZ120)

Brief introduction

The production capacity of DHL600 High-Speed Blister-Cartoning Link Machine can reach 600 blisters/min and 300 cartons/min,suitable for mass production. The whole production line with the concept of advanced technology,original create link machine (1-5) b

Description

Customer Case

Featured Products

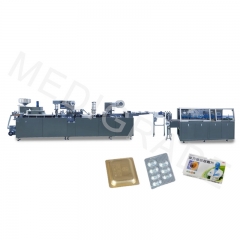

Sample

The production capacity of DHL600 High-Speed Blister-Cartoning Link Machine can reach 600 blisters/min and 300 cartons/min,suitable for mass production.The whole production line with the concept of advanced technology,original create link machine (1-5) blister cartoning production new pattern,can complete switchover (1-5) blister cartoning within one minute,high speed transferred by intelligent flex picker,complete blister cartoning; Leaflet folder can accomplish 300 pages/min (A4 paper).

Overview

DPP-250F11 aluminum/plastic/aluminum blister packaging machine is based on the original DPP-250F type, adopts frequency conversion speed regulation and automatic control technology of machine, electricity, light and gas, and strictly according to the requirements of "GMP" standard of pharmaceutical industry. Innovative design with aluminum plastic, aluminum aluminum, aluminum plastic aluminum packaging function.

1. The DPP series aluminum-plastic aluminum packaging machine produced by our company can be divided into 1.5m elevators and split-type purification workshops. The combination is cylindrical pin positioning and screw fastening, which is easy to assemble.

2. The mold adopts the top plate of the cone plate, and the positioning and loading and unloading of the cylindrical pin is very convenient.

3. The main motor adopts frequency conversion speed regulation: the corresponding number of punching times is set according to factors such as the length of the stroke and the difficulty of feeding the filling.

4. Simultaneously adopt servo and manipulator to clamp the traction double combination mechanism, the operation is stable and the synchronization is accurate, and the stroke can be arbitrarily adjusted within the range of 30-120mm, that is, the plate size can be freely designed within the range. Due to the contact-type plate heating, the heating power and temperature are reduced, energy is saved and the stability of the plastic sheet is increased.

5. The forming heating plate is automatically closed and opened. It can be turned on after the heating plate is put down, and the material waste is limited to a range.

6. The air cushion is heat-sealed, and the cylinder plate is automatically raised by the cylinder when the machine is stopped. It eliminates the deformation phenomenon of the blister caused by heat radiation during staying, and also facilitates the cleaning work of the anilox plate, and at the same time acts as a cushioning function when overpressure, which is beneficial to prolonging the service life of the machine.

7, the upper and lower netting male and female with heat seal, that is, both sides of the front and back are point-like netting. Due to the equal stress on both sides, the plate is flatter and the sealing performance is improved.

8. The PVC is finished and the fragment is automatically stopped. At the same time, it is equipped with an emergency stop safety device, which improves the safety of the operator in debugging and changing the mold.

10. All parts and hoppers that come into contact with drugs are made of stainless steel and non-toxic materials, which meet the requirements of "GMP".

XWZ-120 automatic vertical automatic cartoning machine This equipment is a high-tech product integrating light, electricity, gas and machine. It is suitable for automatic packaging of medicines, aluminum-plastic blister packaging plates or medicinal products, small long-body regular items, foods, cosmetics, etc. It can automatically complete the complicated packaging process such as folding of the manual, opening of the paper tray, box loading, printing batch number, sealing and so on.

The device is compact and reasonable in structure, stable in performance and advanced in operation. It is easy to understand and easy to understand. It adopts PLCA automatic control system with variable frequency speed control, human-machine interface operating system, high-intensity photoelectric monitoring of various parts of the action, abnormal operation, and can automatically display the reason for timely elimination. malfunction. It can be connected with blister packaging machines and other equipment to form a complete production line.

Innovation

1. The whole line is designed and manufactured according to the space space of the current GMP standard workshop.

2. Separate design of each functional area of the whole line, using German imported photoelectric eye tracking and detection to automatically control the entire line operation.

3. The movement of each station in the whole line has a very high electronic automatic synchronism, which makes the operation of the whole line more coordinated, more balanced and low noise.

4. This line integrates aluminum-plastic aluminum, box packaging and packaging, simple operation, PLC programmable control, touch human-machine interface.

5. High degree of automation, wide control range, high control precision, sensitive control response and good stability.

6. This production line can not only be produced in linkage, but also can be produced in a single machine.

7. The number of parts is small, the structure of the machine is simple, and the maintenance is convenient.

8. Low decibel design, ergonomic application.

9. The aluminum-plastic aluminum and the box are connected by a continuous conveying system to ensure multi-machine linkage.

Min Technical Parameter

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

The production capacity of DHL600 High-Speed Blister-Cartoning Link Machine can reach 600 blisters/min and 300 cartons/min,suitable for mass production.The whole production line with the concept of advanced technology,original create link machine (1-5) blister cartoning production new pattern,can complete switchover (1-5) blister cartoning within one minute,high speed transferred by intelligent flex picker,complete blister cartoning; Leaflet folder can accomplish 300 pages/min (A4 paper).

Overview

DPP-250F11 aluminum/plastic/aluminum blister packaging machine is based on the original DPP-250F type, adopts frequency conversion speed regulation and automatic control technology of machine, electricity, light and gas, and strictly according to the requirements of "GMP" standard of pharmaceutical industry. Innovative design with aluminum plastic, aluminum aluminum, aluminum plastic aluminum packaging function.

1. The DPP series aluminum-plastic aluminum packaging machine produced by our company can be divided into 1.5m elevators and split-type purification workshops. The combination is cylindrical pin positioning and screw fastening, which is easy to assemble.

2. The mold adopts the top plate of the cone plate, and the positioning and loading and unloading of the cylindrical pin is very convenient.

3. The main motor adopts frequency conversion speed regulation: the corresponding number of punching times is set according to factors such as the length of the stroke and the difficulty of feeding the filling.

4. Simultaneously adopt servo and manipulator to clamp the traction double combination mechanism, the operation is stable and the synchronization is accurate, and the stroke can be arbitrarily adjusted within the range of 30-120mm, that is, the plate size can be freely designed within the range. Due to the contact-type plate heating, the heating power and temperature are reduced, energy is saved and the stability of the plastic sheet is increased.

5. The forming heating plate is automatically closed and opened. It can be turned on after the heating plate is put down, and the material waste is limited to a range.

6. The air cushion is heat-sealed, and the cylinder plate is automatically raised by the cylinder when the machine is stopped. It eliminates the deformation phenomenon of the blister caused by heat radiation during staying, and also facilitates the cleaning work of the anilox plate, and at the same time acts as a cushioning function when overpressure, which is beneficial to prolonging the service life of the machine.

7, the upper and lower netting male and female with heat seal, that is, both sides of the front and back are point-like netting. Due to the equal stress on both sides, the plate is flatter and the sealing performance is improved.

8. The PVC is finished and the fragment is automatically stopped. At the same time, it is equipped with an emergency stop safety device, which improves the safety of the operator in debugging and changing the mold.

10. All parts and hoppers that come into contact with drugs are made of stainless steel and non-toxic materials, which meet the requirements of "GMP".

XWZ-120 automatic vertical automatic cartoning machine This equipment is a high-tech product integrating light, electricity, gas and machine. It is suitable for automatic packaging of medicines, aluminum-plastic blister packaging plates or medicinal products, small long-body regular items, foods, cosmetics, etc. It can automatically complete the complicated packaging process such as folding of the manual, opening of the paper tray, box loading, printing batch number, sealing and so on.

The device is compact and reasonable in structure, stable in performance and advanced in operation. It is easy to understand and easy to understand. It adopts PLCA automatic control system with variable frequency speed control, human-machine interface operating system, high-intensity photoelectric monitoring of various parts of the action, abnormal operation, and can automatically display the reason for timely elimination. malfunction. It can be connected with blister packaging machines and other equipment to form a complete production line.

Innovation

1. The whole line is designed and manufactured according to the space space of the current GMP standard workshop.

2. Separate design of each functional area of the whole line, using German imported photoelectric eye tracking and detection to automatically control the entire line operation.

3. The movement of each station in the whole line has a very high electronic automatic synchronism, which makes the operation of the whole line more coordinated, more balanced and low noise.

4. This line integrates aluminum-plastic aluminum, box packaging and packaging, simple operation, PLC programmable control, touch human-machine interface.

5. High degree of automation, wide control range, high control precision, sensitive control response and good stability.

6. This production line can not only be produced in linkage, but also can be produced in a single machine.

7. The number of parts is small, the structure of the machine is simple, and the maintenance is convenient.

8. Low decibel design, ergonomic application.

9. The aluminum-plastic aluminum and the box are connected by a continuous conveying system to ensure multi-machine linkage.

Min Technical Parameter

|

Capacity (Cycle/min )

|

20-40 (cycle/min)

|

|

|

Packing material:

|

Range of stroke(mm)

|

40-120

|

|

Pharmacy PVC(mm)

|

(0.2-0.5) x 250

|

|

|

PTP alu foil (mm)

|

(0.02-0.05) x 250

|

|

|

Tropical alu (mm)

|

(0.09-0.15)x250

|

|

|

Clean compressed air (pressure)

|

0.5~0.7MPa

|

|

|

Air consumption (m³/h)

|

≥0.3

|

|

|

Power (mm)

|

AC 380V 50Hz 12Kw

|

|

|

Water chiller for moulds

|

Tap water or recyle water with 60L/h consumption

|

|

|

Overall dimension (LxWxH)(mm)

|

4890 x 650 x 1700

|

|

|

Net Weight

|

2600kg

|

|

|

capacity (Cartons/min )

|

30-120 cartons/min

|

|

|

Packing material:

|

Box dimension (LxWx H)(mm)

|

(75-180)x(35-85)x(15-65)

|

|

Cardboard of box required

|

280-350 (g/m²)

|

|

|

Leaflet dimension (LxW)(mm)

|

(90-260)x(90-180)

|

|

|

Leaflet paper required

|

50-70 (g/m²)

|

|

|

Clean compressed air (pressure)(Mpa)

|

0.5~0.7 Mpa

|

|

|

Air consumption (m³/h)

|

≥0.3

|

|

|

Power (mm)

|

AC220V 50HZ 1KW

|

|

|

Overall dimension (LxWxH)

|

3650 x 1240 x 1610mm

|

|

|

Net Weight

|

1700kg

|

|

If you are interested in this, please contact me: Nana Zhang

Cell Phone: 0086-15800947006

https://medigrade.en.made-in-china.com/ made-in-china.com

Customer Case

Featured Products

All the main parts are made of premium stainless steel and alu-alloy material and machined by advanced high-precision CNC tooling machines.

Pharmaceutical Research and Development laboratories, Clinical trials, Stability studies, Package development, Marketing, samples, Pharmaceutical production, and packaging departments.